Electronics & Engineering Services

From concept to production — MAKS Inc. offers complete electronics design and manufacturing services, along with custom software development and full in-house assembly. As your trusted partner, we support every stage from prototype to production.

What We Offer

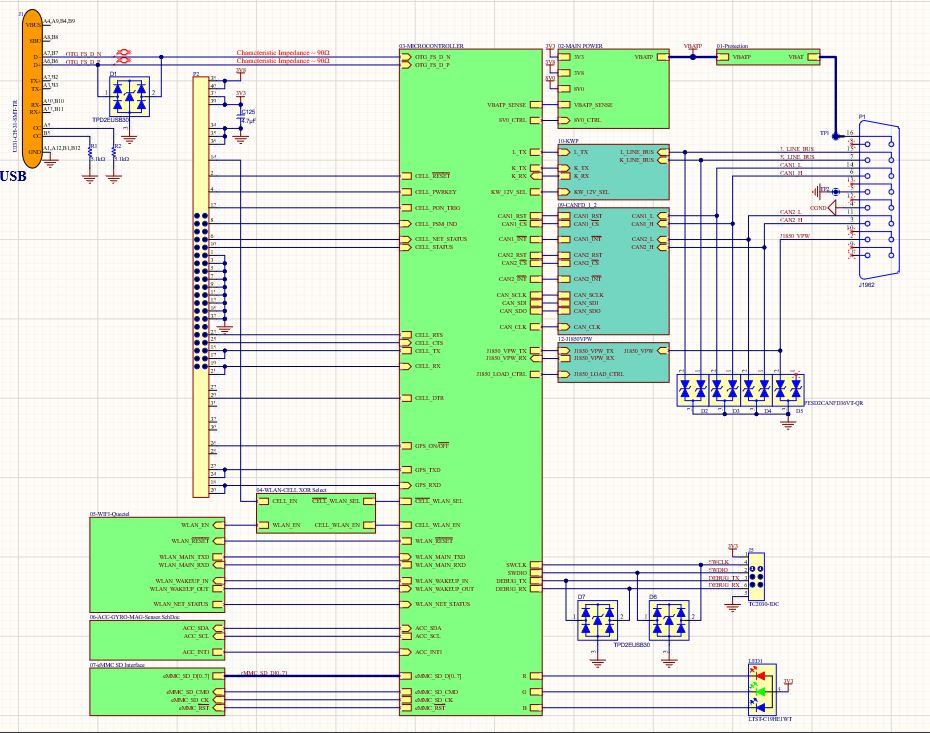

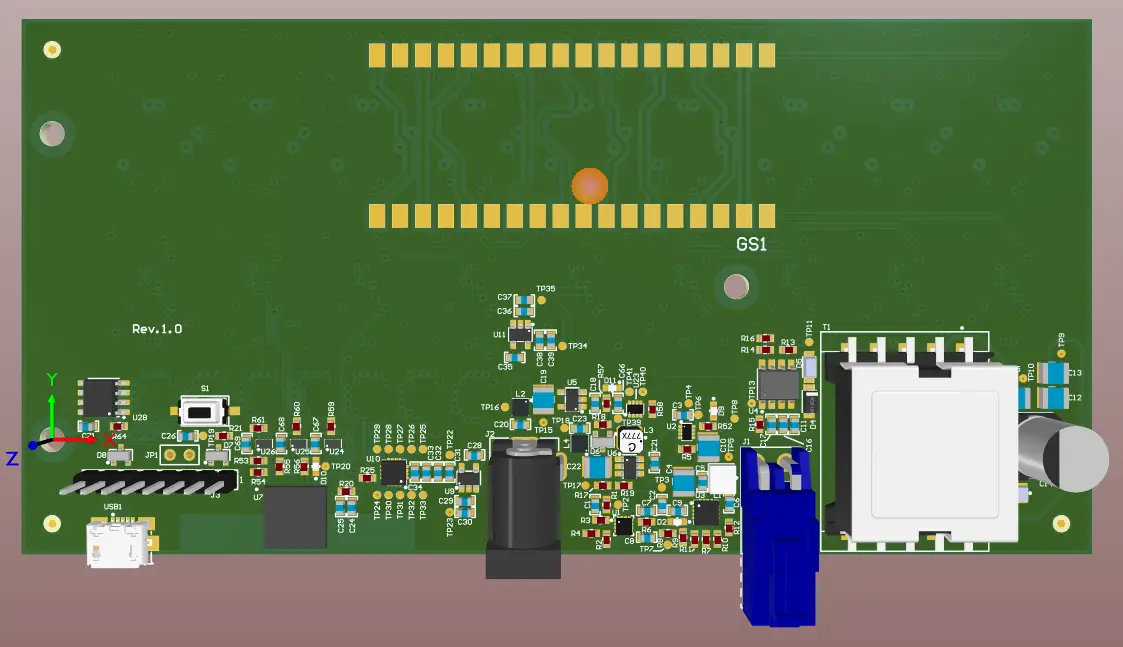

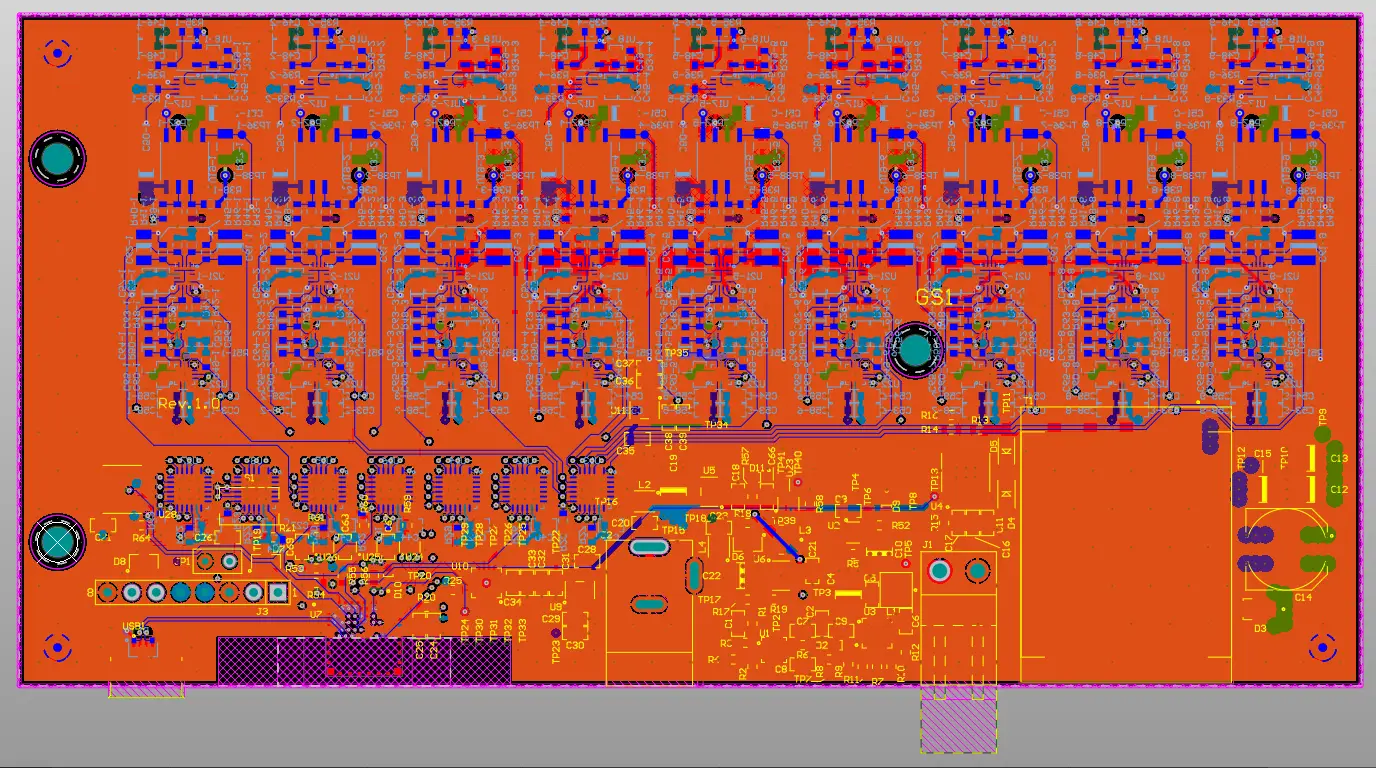

PCB Design & Circuit Layout Engineering

Our engineering team transforms your concepts into production-ready PCBs — and beyond. From schematic capture and multi-layer layout to complete product integration in enclosures, we ensure precision, manufacturability, and cost-efficiency. In addition, we support design for manufacturing (DFM) and collaborate closely with your team from day one.

SMT & Through-Hole PCB Assembly

We provide turnkey PCB assembly services for both surface-mount (SMT) and through-hole components. Whether you need prototypes or full production, we handle parts sourcing, soldering, reflow, X-ray inspection, AOI, and functional testing — all in-house. Moreover, our processes include full traceability and are designed to ensure speed, precision, and quality at every step.

Precision BGA Rework & Replacement

We offer high-precision BGA rework services using advanced rework stations. Whether it’s reballing, replacing, or reflowing BGA components, our process ensures alignment accuracy, thermal control, and high reliability — ideal for prototypes, repairs, or small batch corrections.

Wire Harness & Cable Assembly

MAKS Inc. builds custom wire and cable harnesses to exact customer specifications. We support automotive, medical, and industrial standards with high-quality crimps, labeling, bundling, and routing. In fact, these assemblies are a key part of our electronics design and manufacturing services, especially for automotive and medical applications. Whether for prototypes or production, we ensure every harness is durable, accurate, and ready for integration.

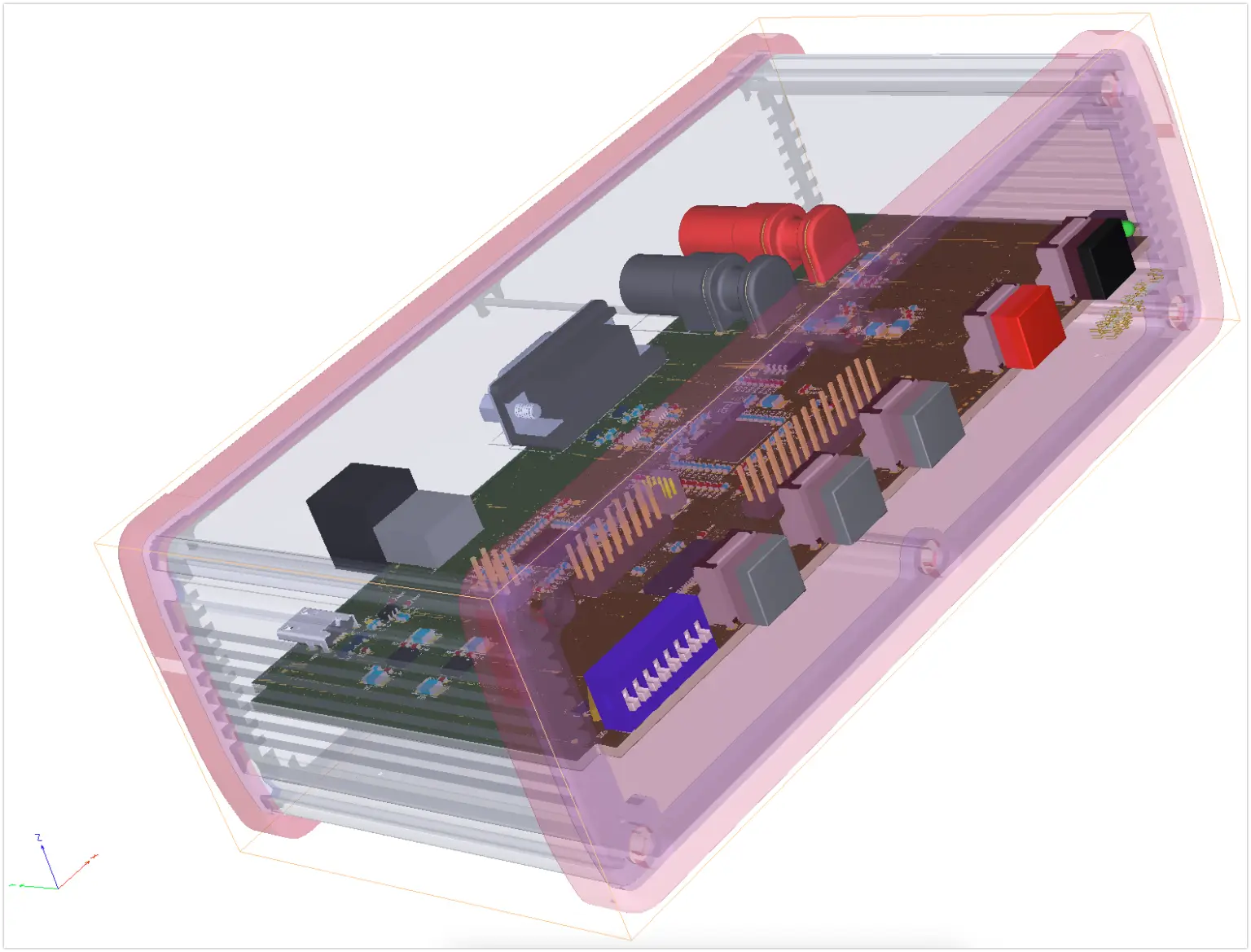

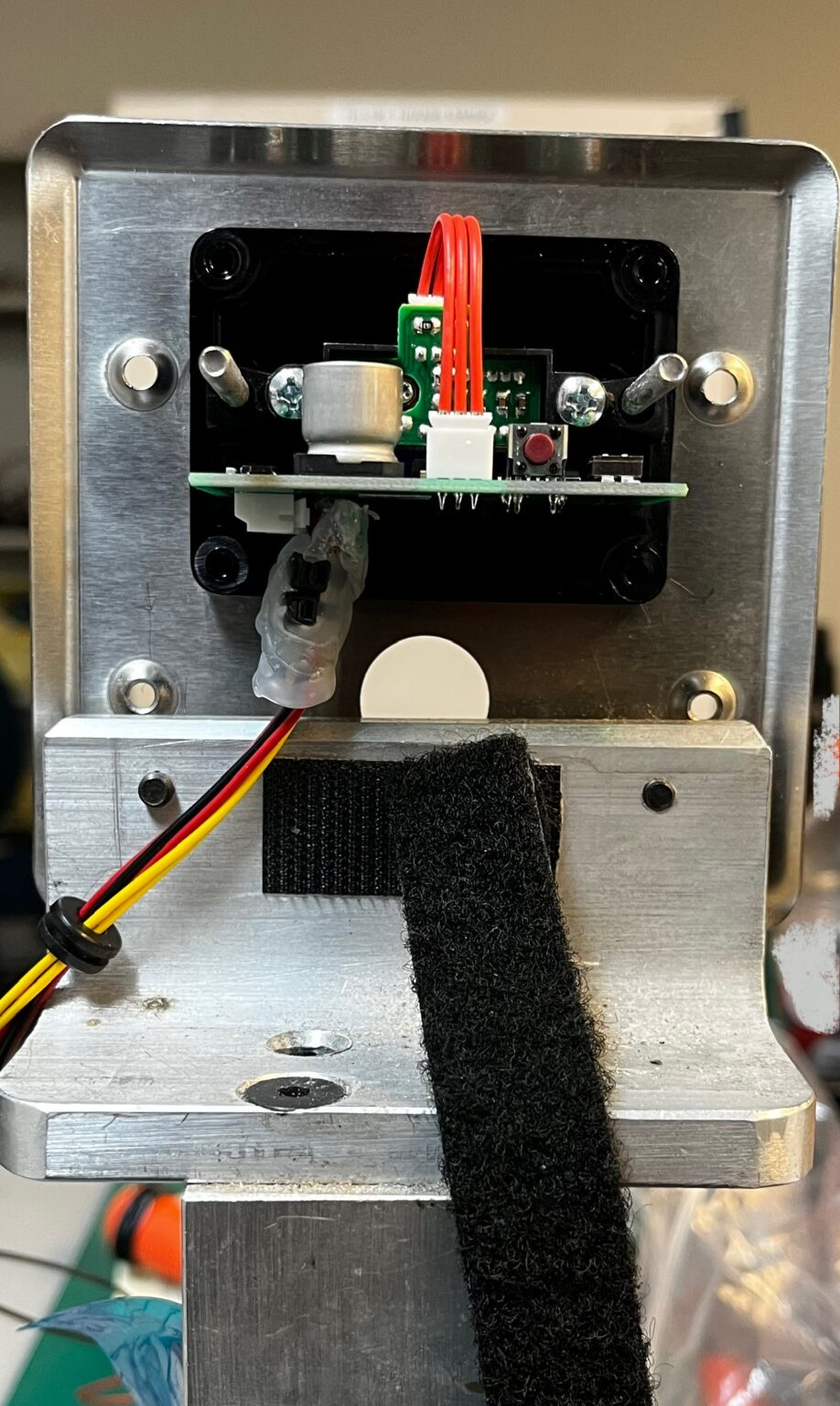

Final Assembly & Potting in Electronics Design and Manufacturing

MAKS Inc. provides complete electronics design and manufacturing services, including electromechanical assembly, box builds, enclosure integration, and protective potting. Additionally, we handle connector installation, labeling, testing, and packaging — all in-house. As a result, our team ensures every unit is reliable, traceable, and production-ready.

3D Printing for Prototyping & Production Support

We use in-house 3D printing to accelerate prototyping and support production. For example, from custom brackets and spacers to fixtures and enclosures, our printing capability helps reduce lead times and improve fit-and-function validation. Consequently, it adds flexibility to both development and assembly phases.

Custom Testing Fixtures Built In-House

MAKS Inc. designs and builds custom test fixtures to support functional validation, production testing, and quality assurance. In particular, our team creates fixtures tailored to each project, ensuring accurate and repeatable results — even for complex assemblies. This approach enhances consistency and reduces testing time.

Let’s Bring Your Next Project to Life

From concept to production — MAKS Inc. is ready to support your electronics and software projects with expert engineering and electronics design and manufacturing services. Whether you’re building a prototype, scaling to production, or looking for a turnkey partner, we’re here to help