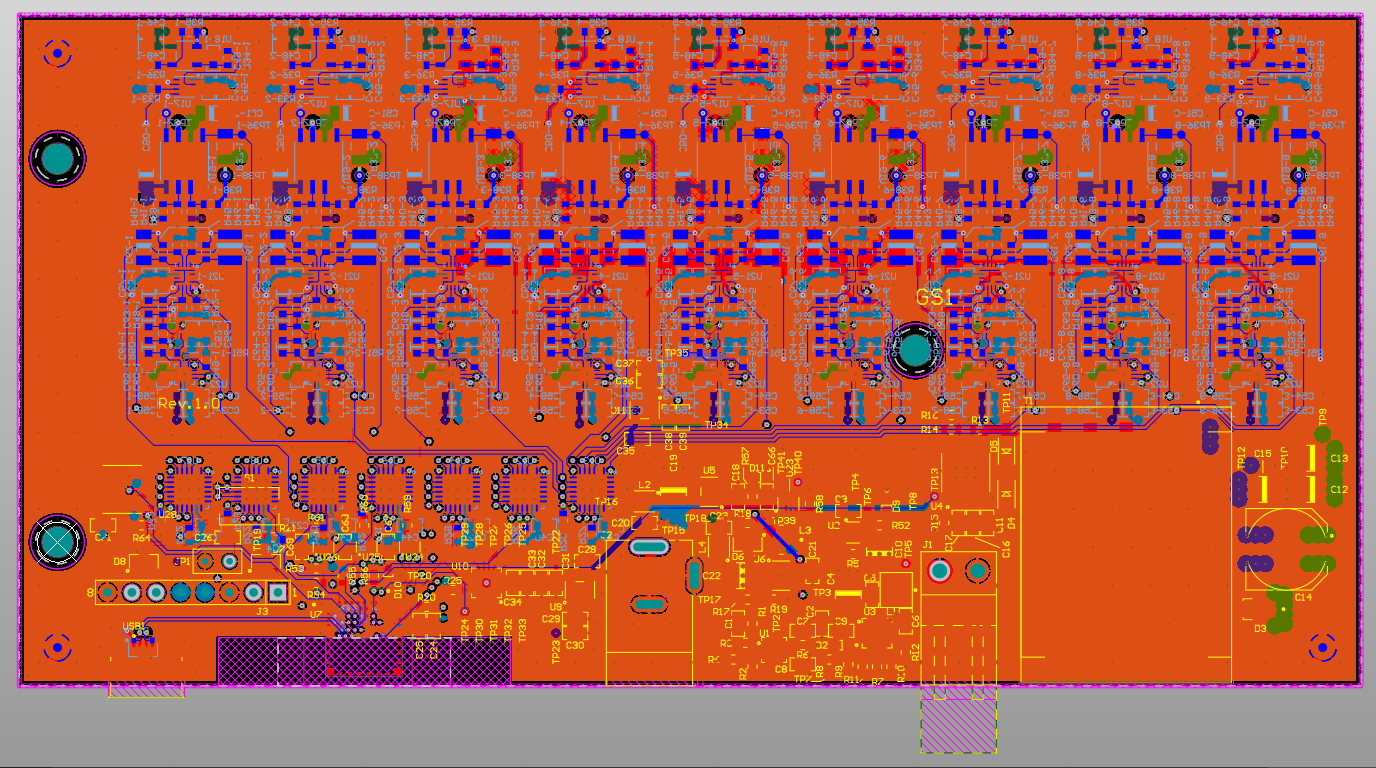

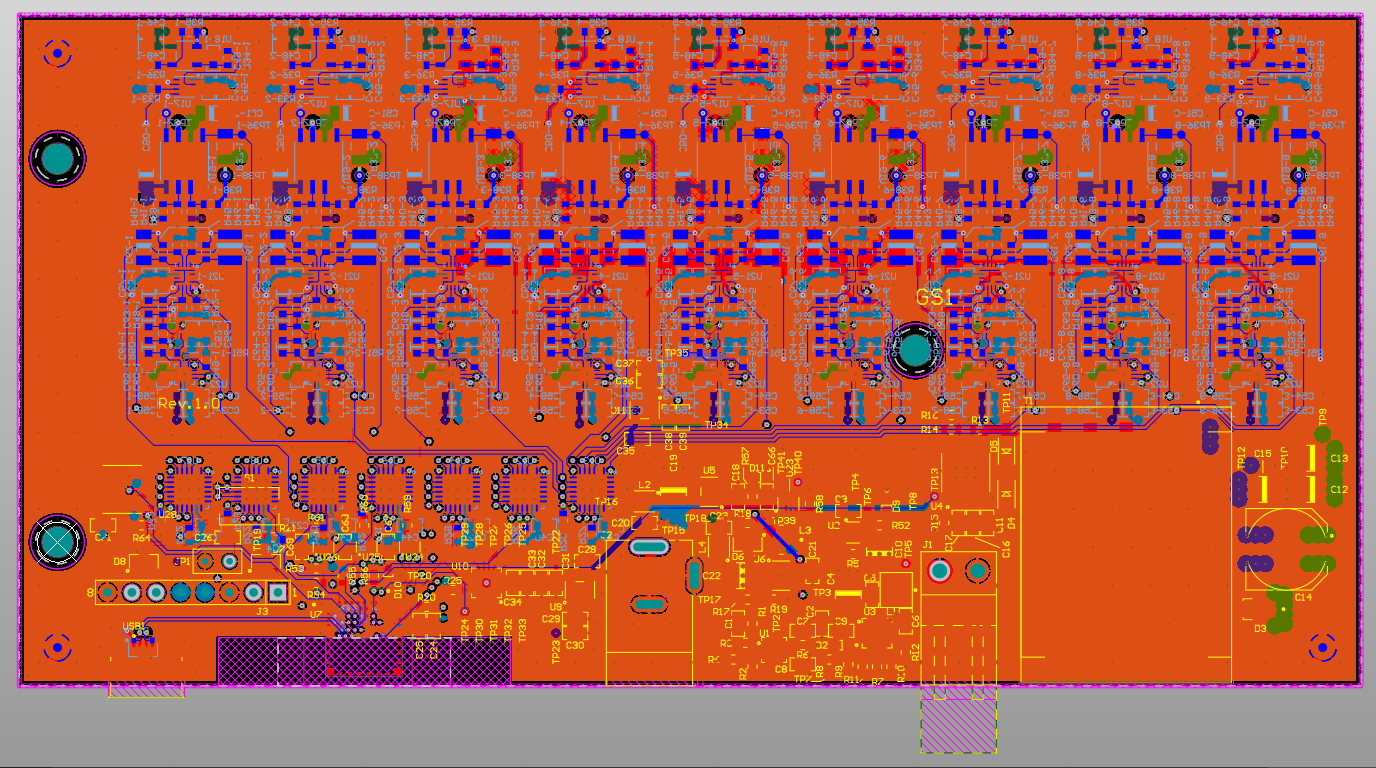

What we offer

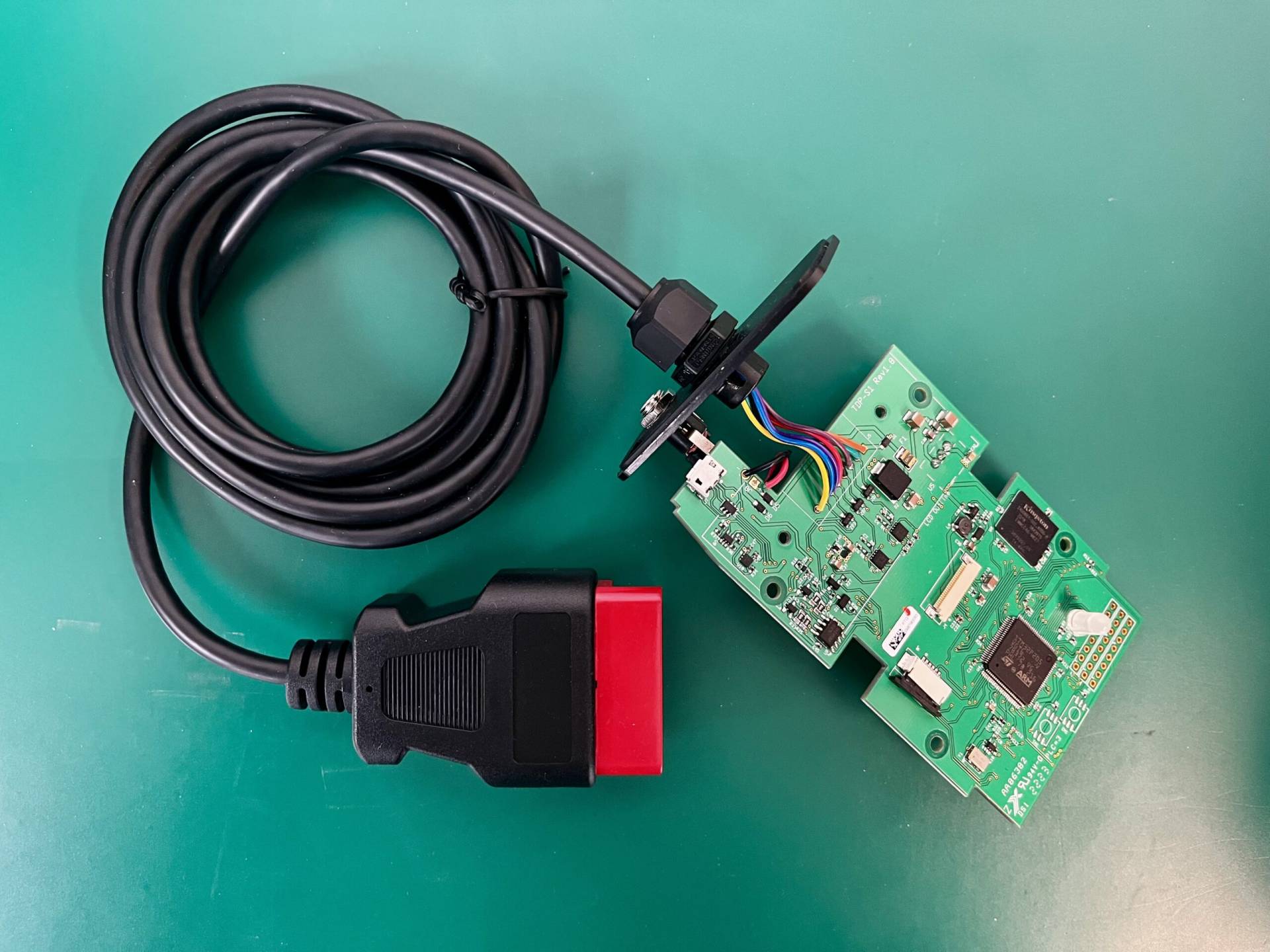

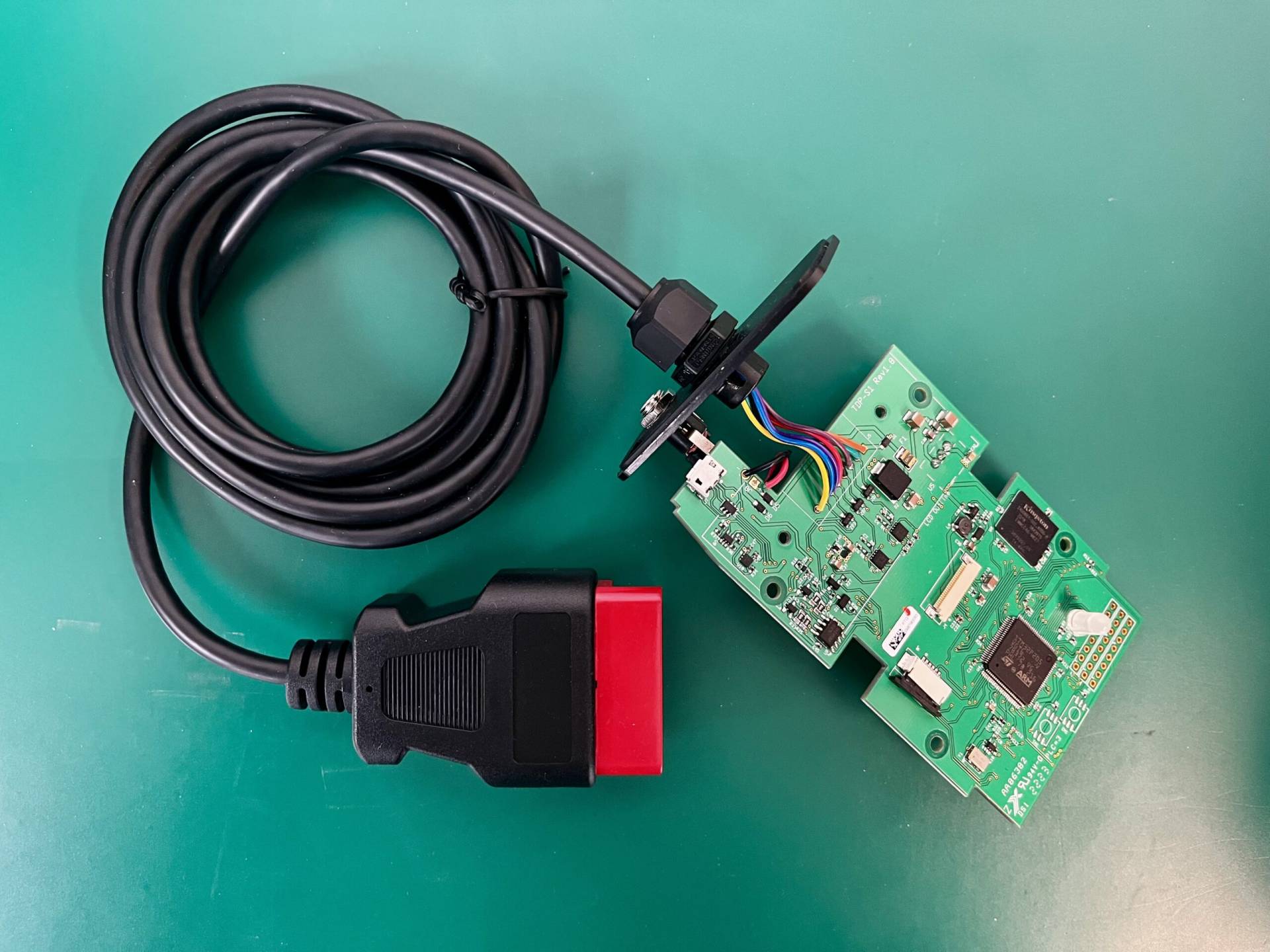

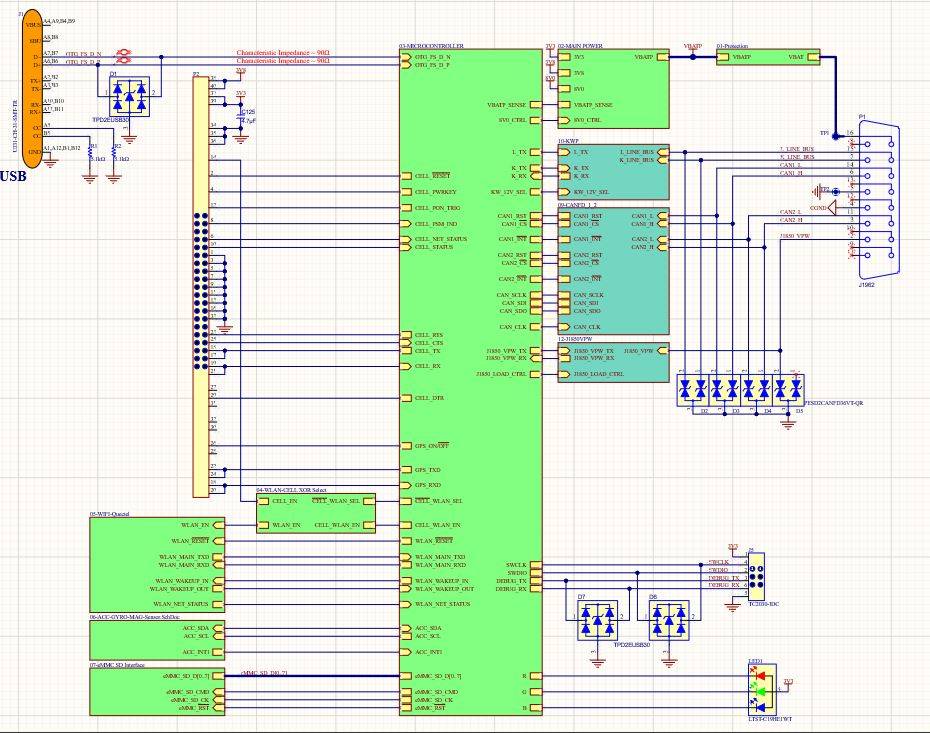

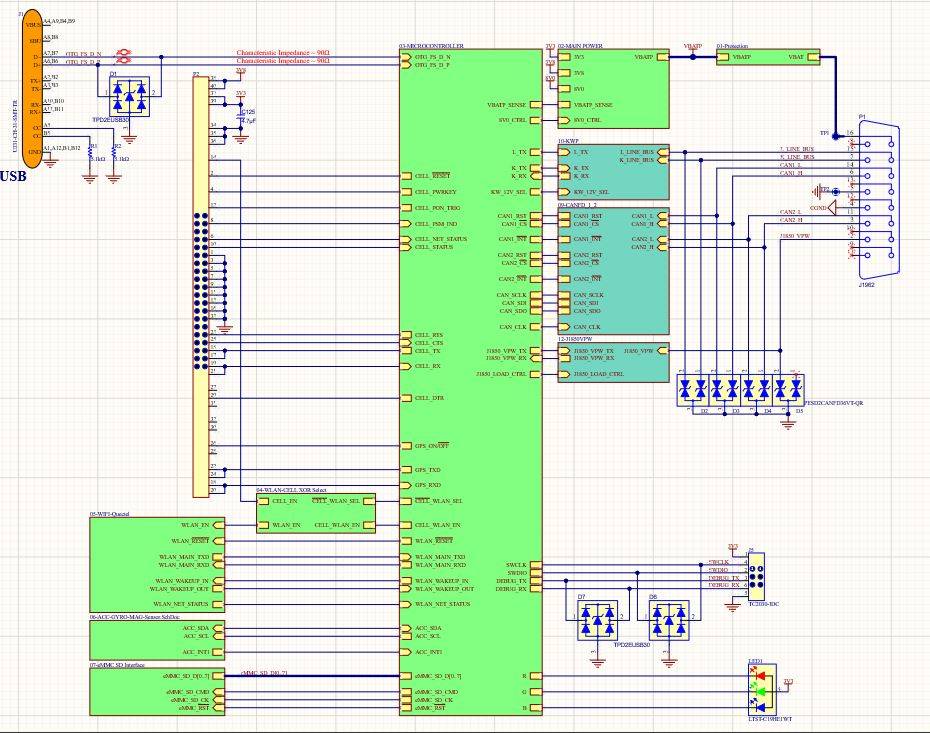

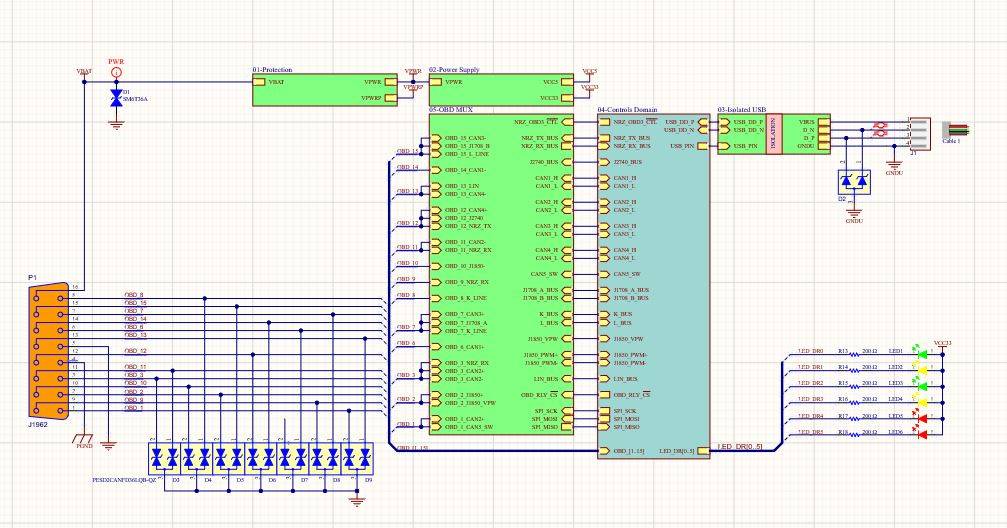

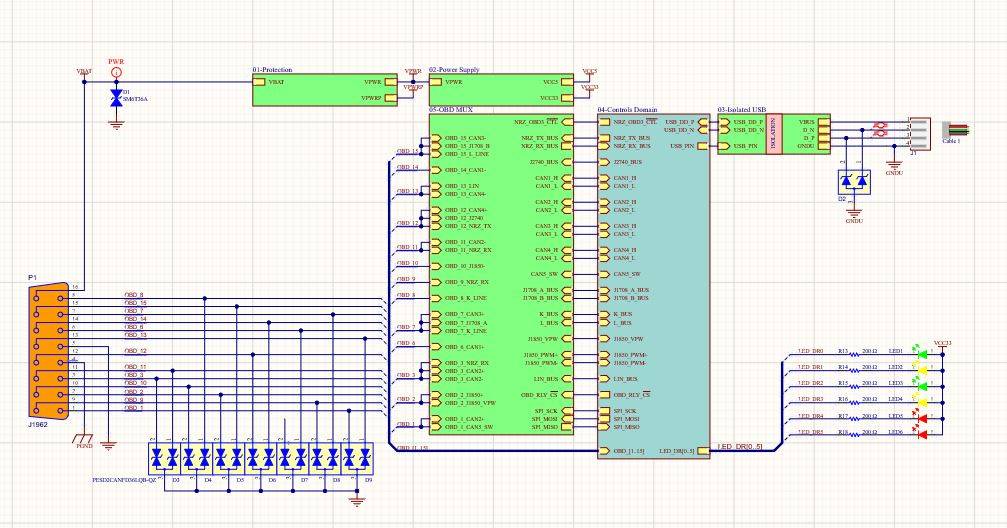

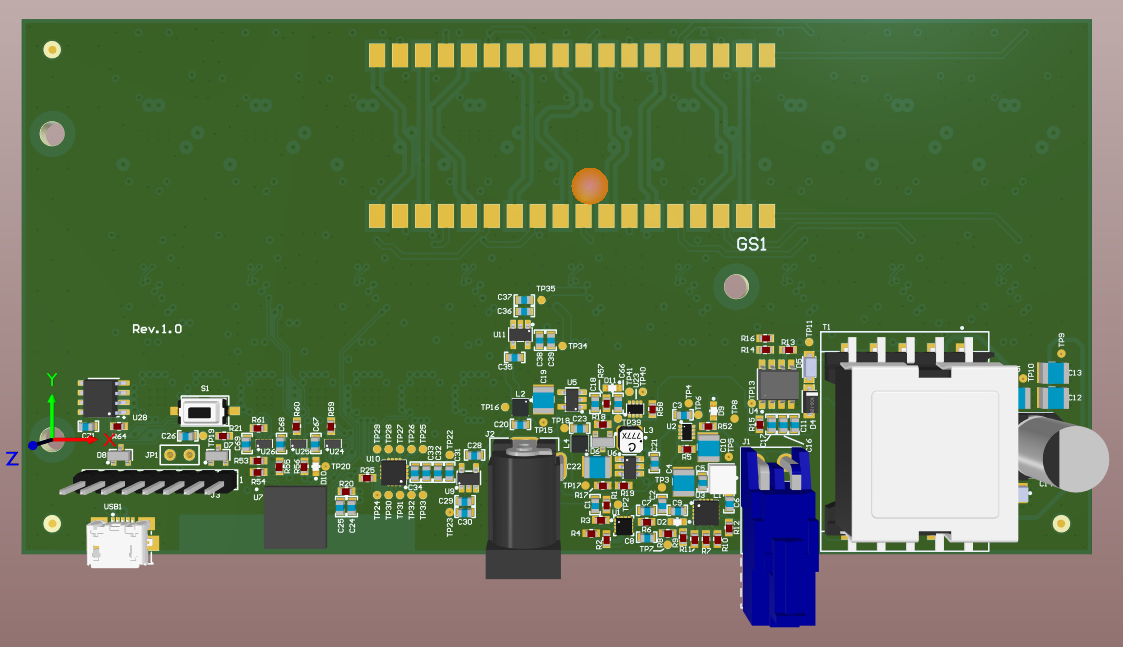

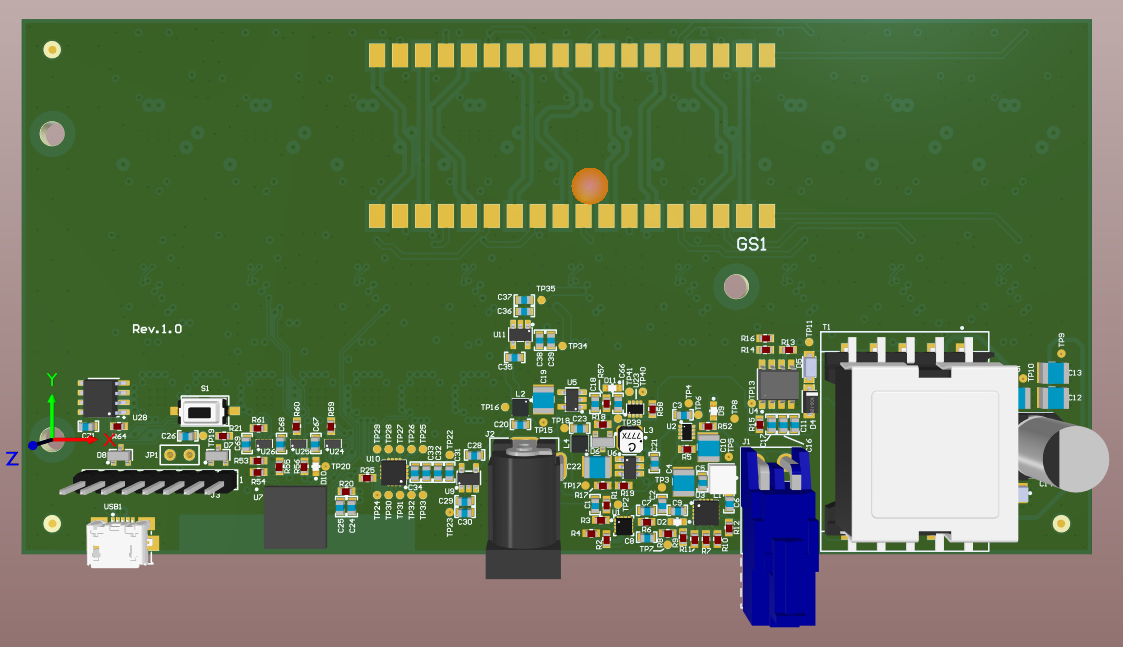

At MAKS, we specialize in PCB layout and design engineering, delivering tailored solutions from concept to production with precision and expertise.

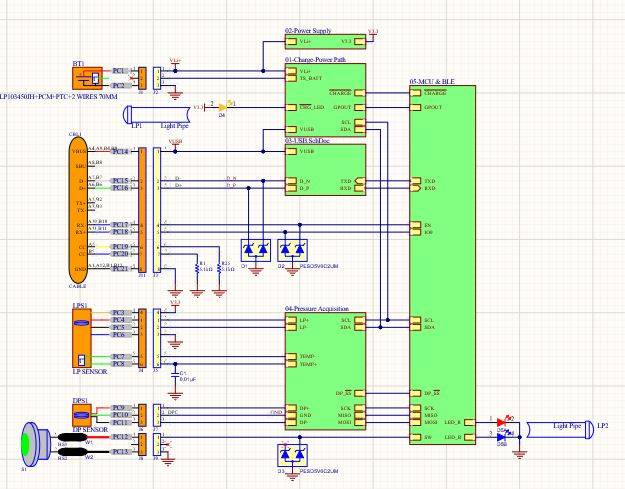

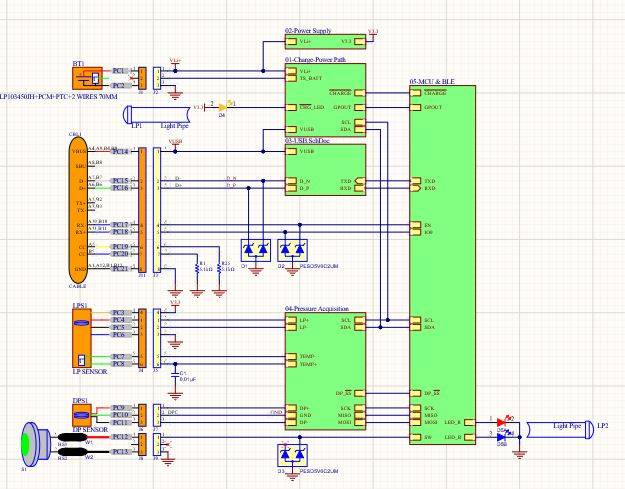

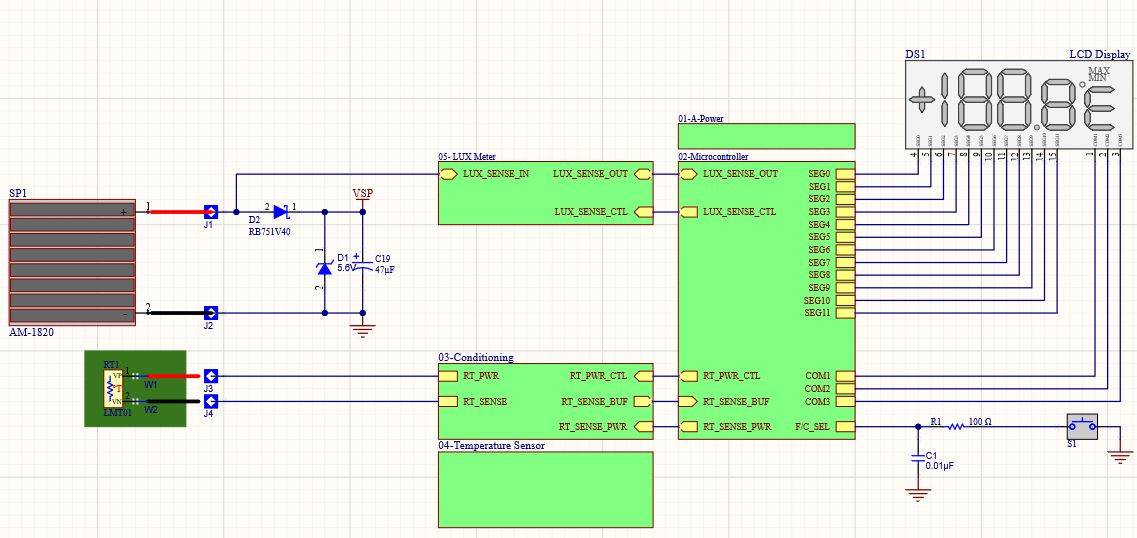

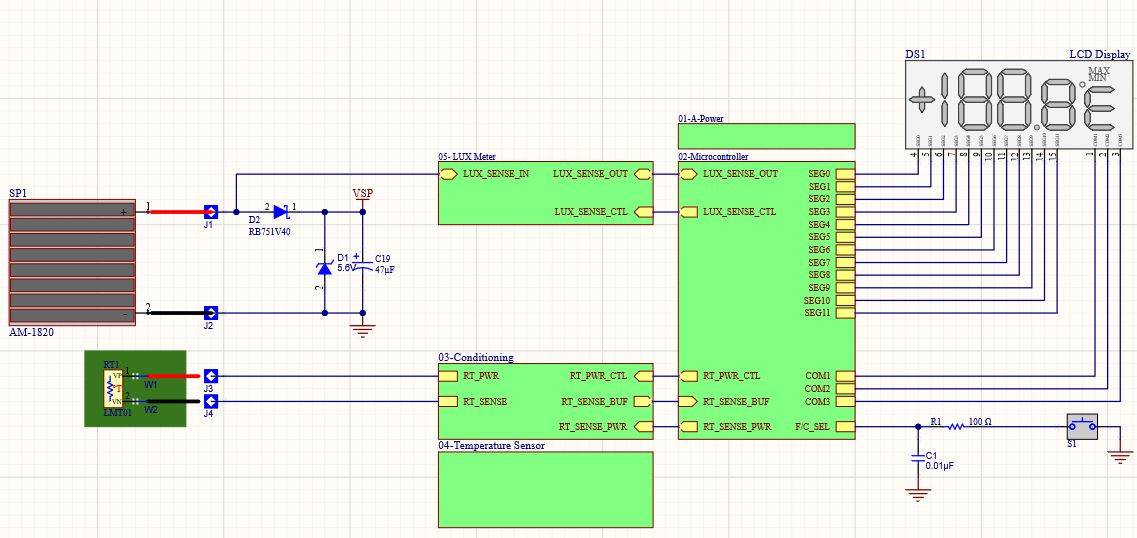

Our expert engineering team creates tailored solutions from schematic design to PCB layout, delivering precision and innovation at every step.

*Not certified for ISO 9001:2015

MAKS also specializes in software engineering, from embedded systems in C to high-level applications for desktop, mobile, tablet, web, and cross-platform environments using technologies like .NET, C#, Flutter, and Python. Our expertise spans everything from database design to seamless cloud deployment on platforms like Azure, delivering end-to-end software solutions tailored to your needs.

- C programming for embedded software

- Flutter for cross-platform (web, desktop, tablet & phone) programming to communicate with your devices

- Vue.js for web-based application

- .NET and C# for cross-platform web-based application and SQL Server database intregration

- Python for desktop applications that communicate with your devices

*Not certified for ISO 9001:2015

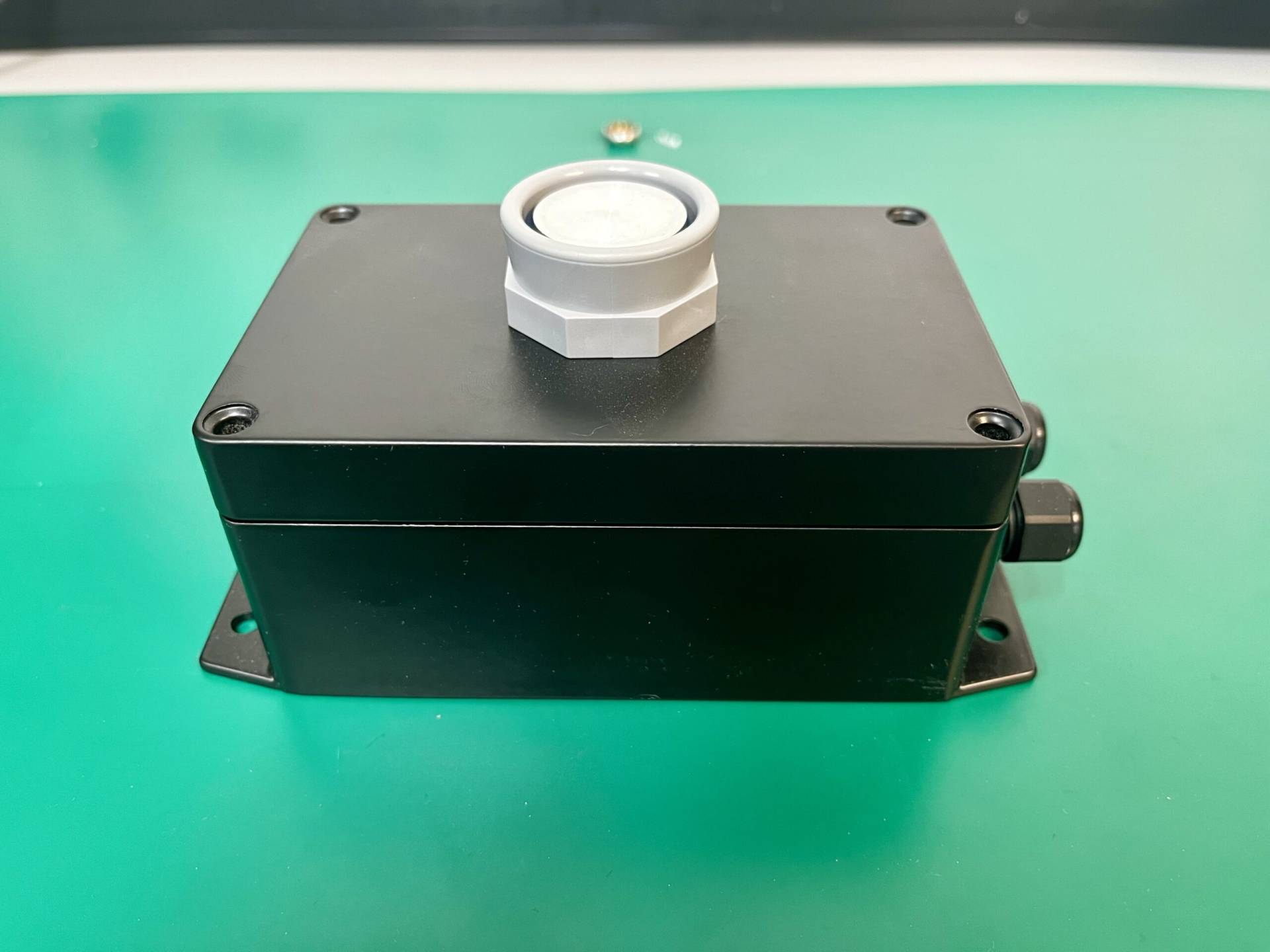

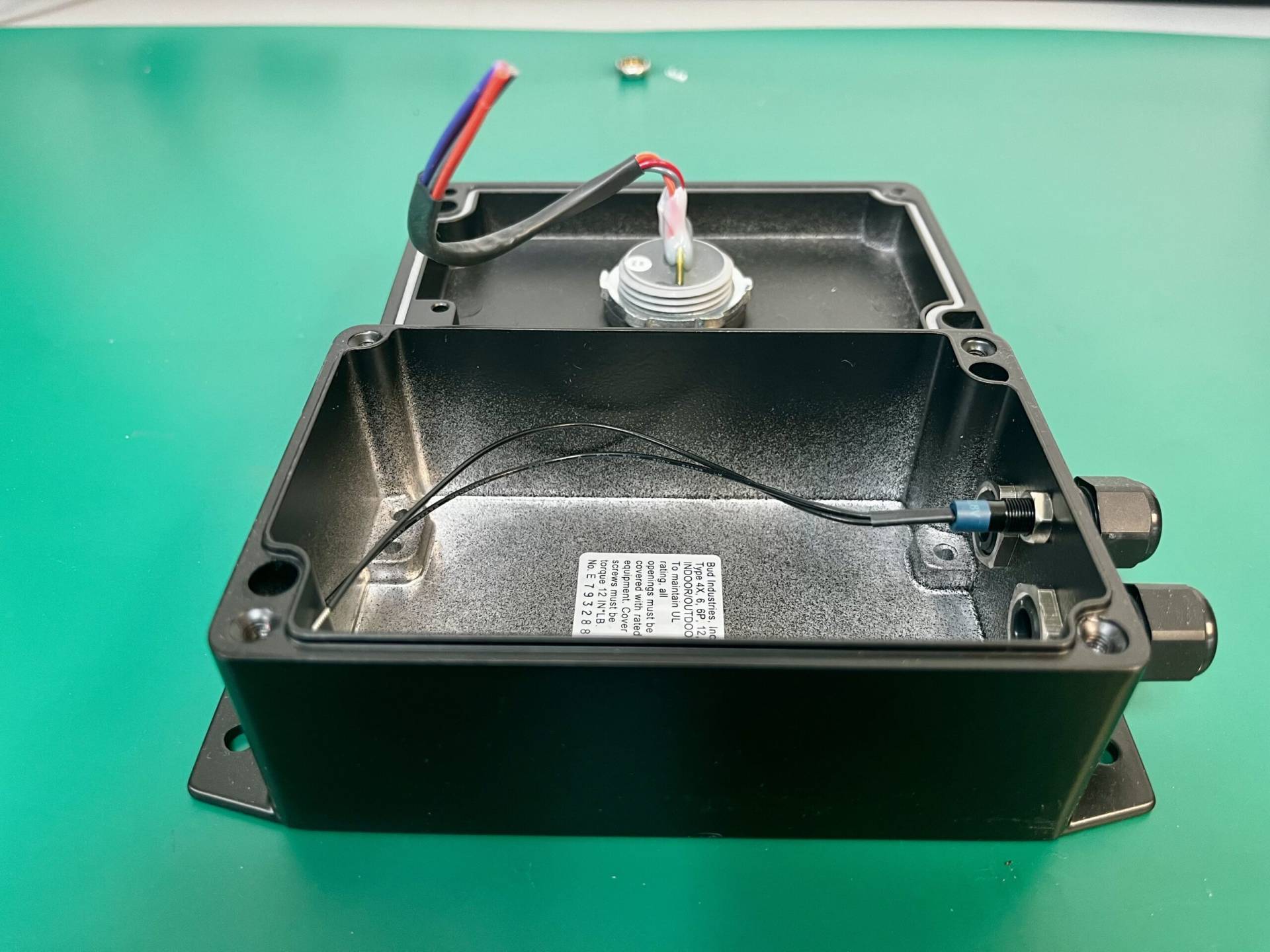

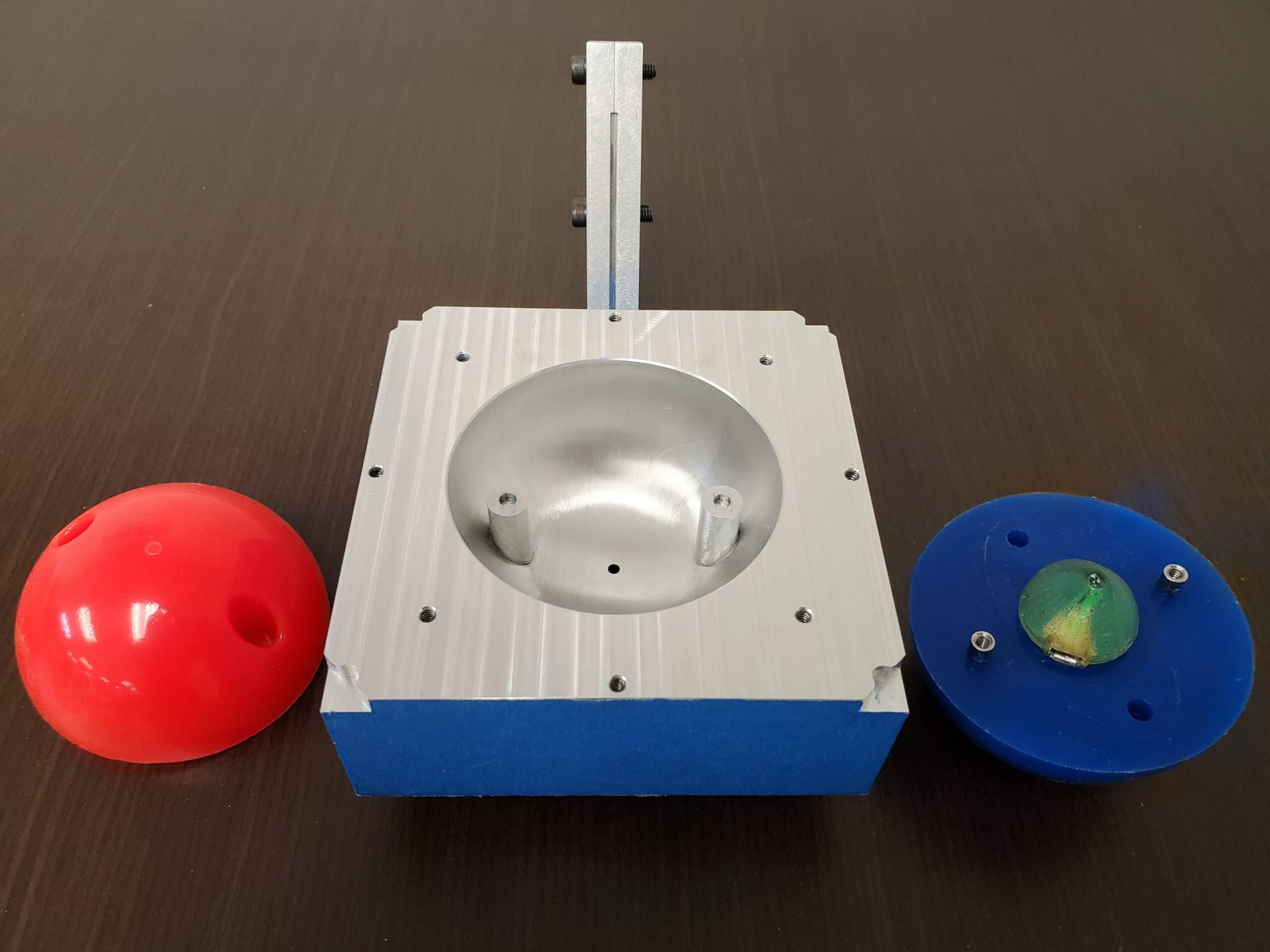

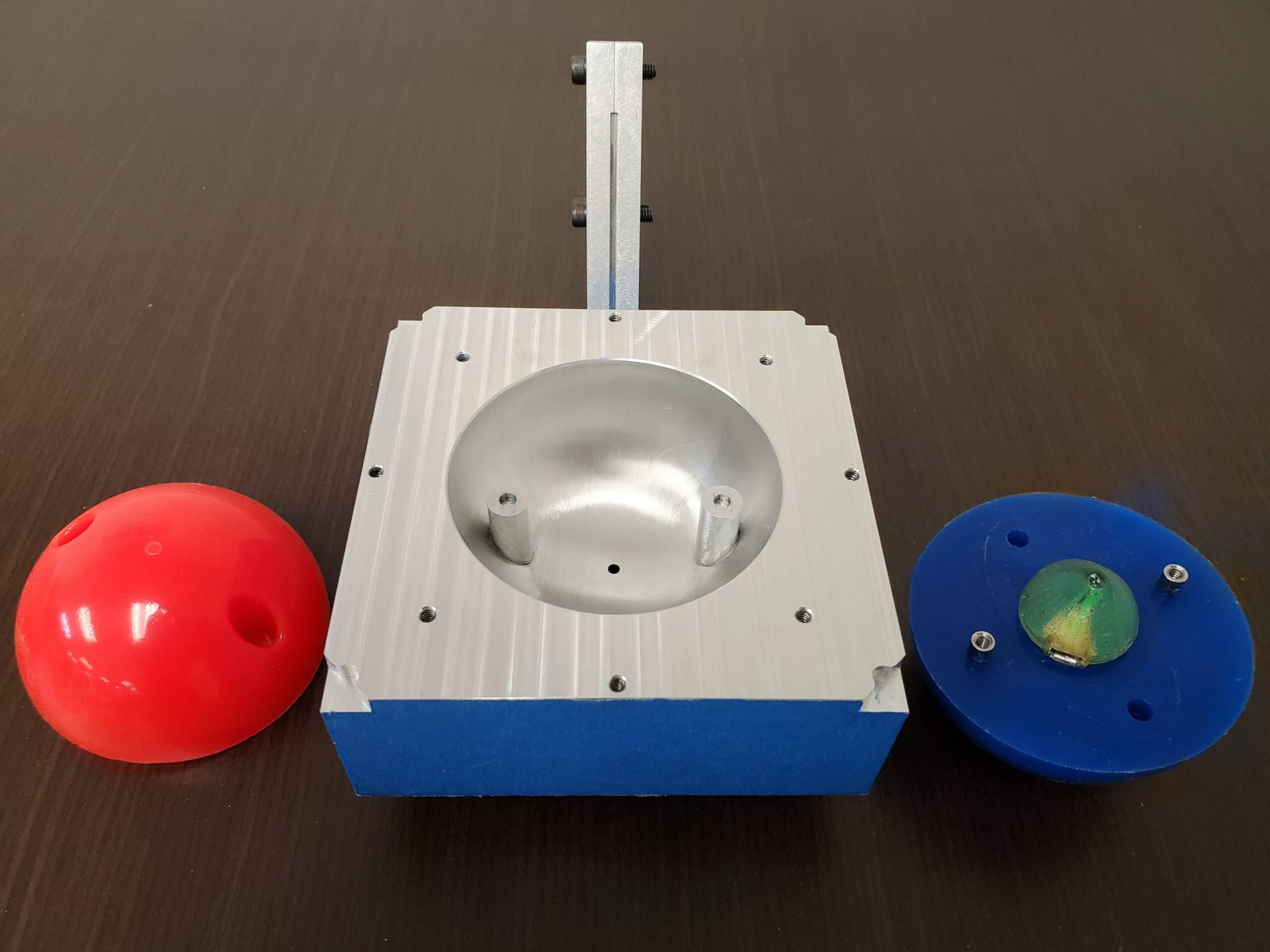

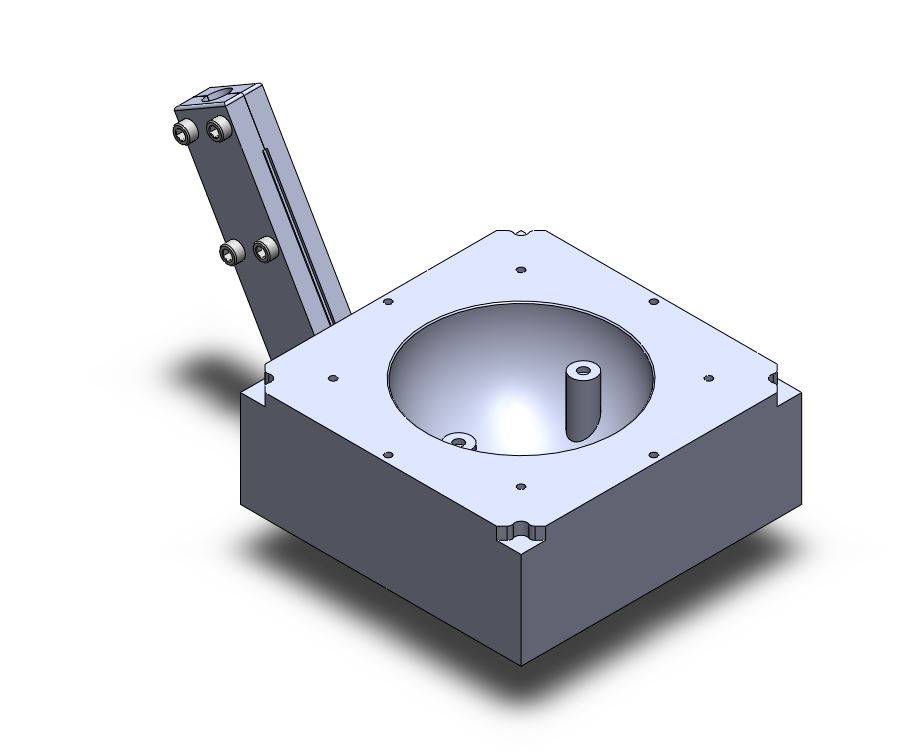

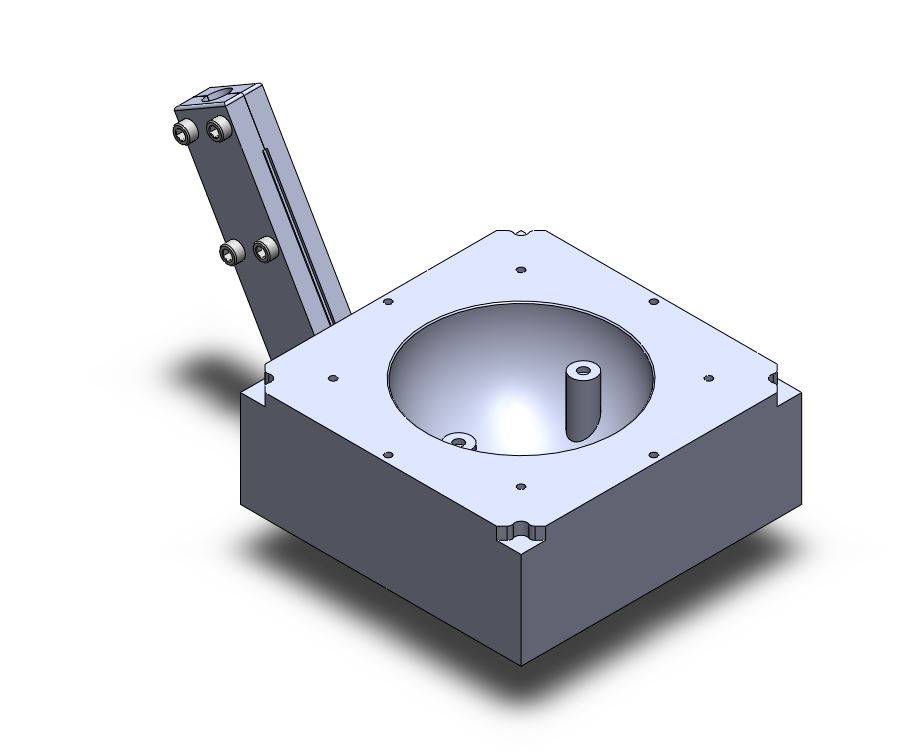

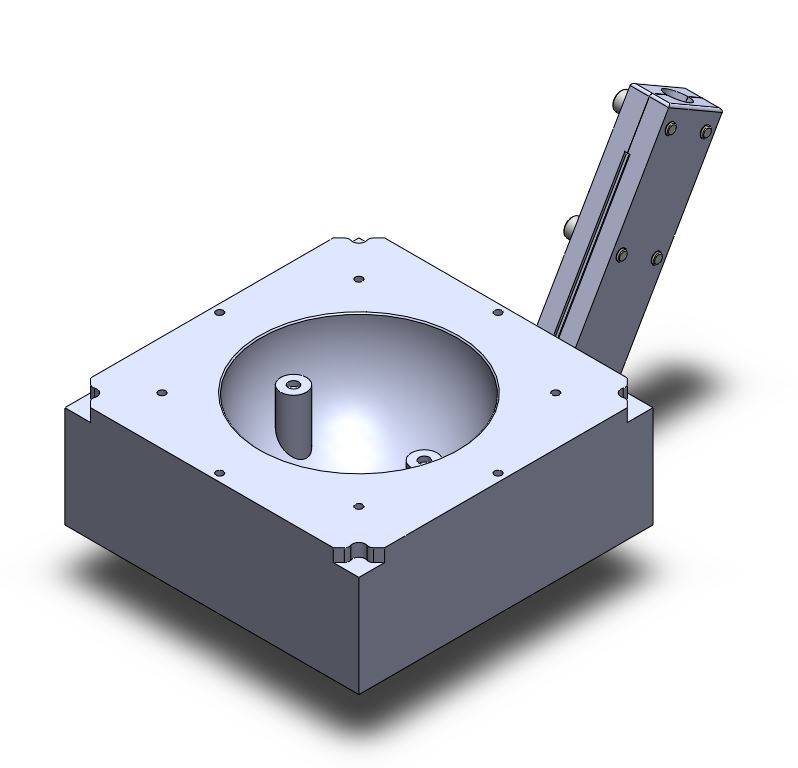

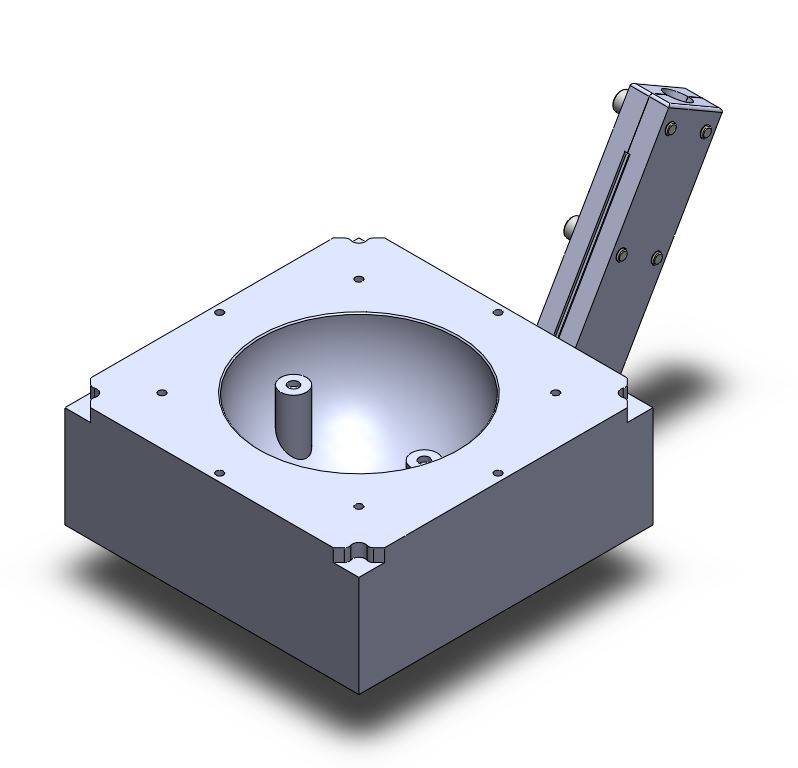

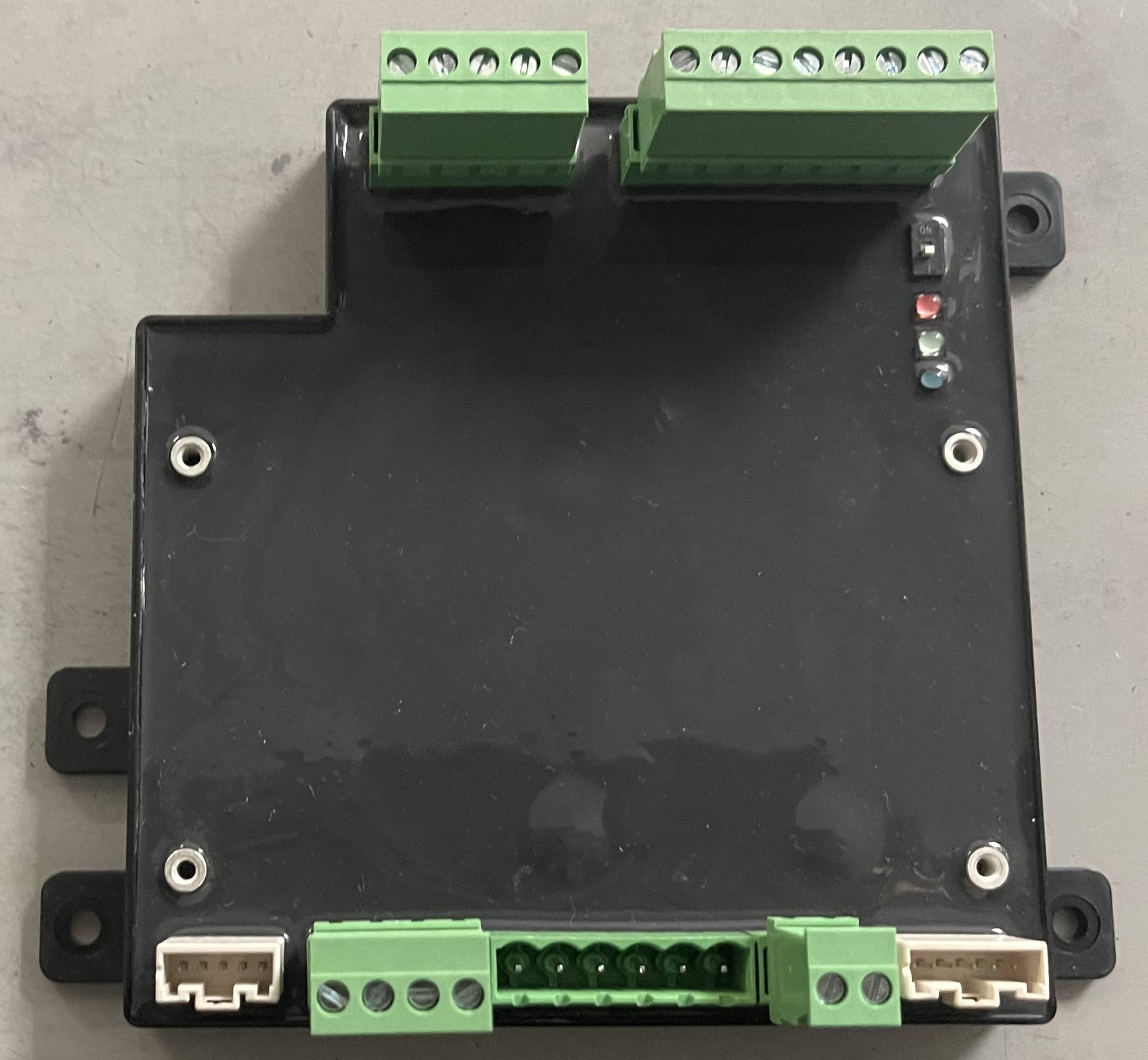

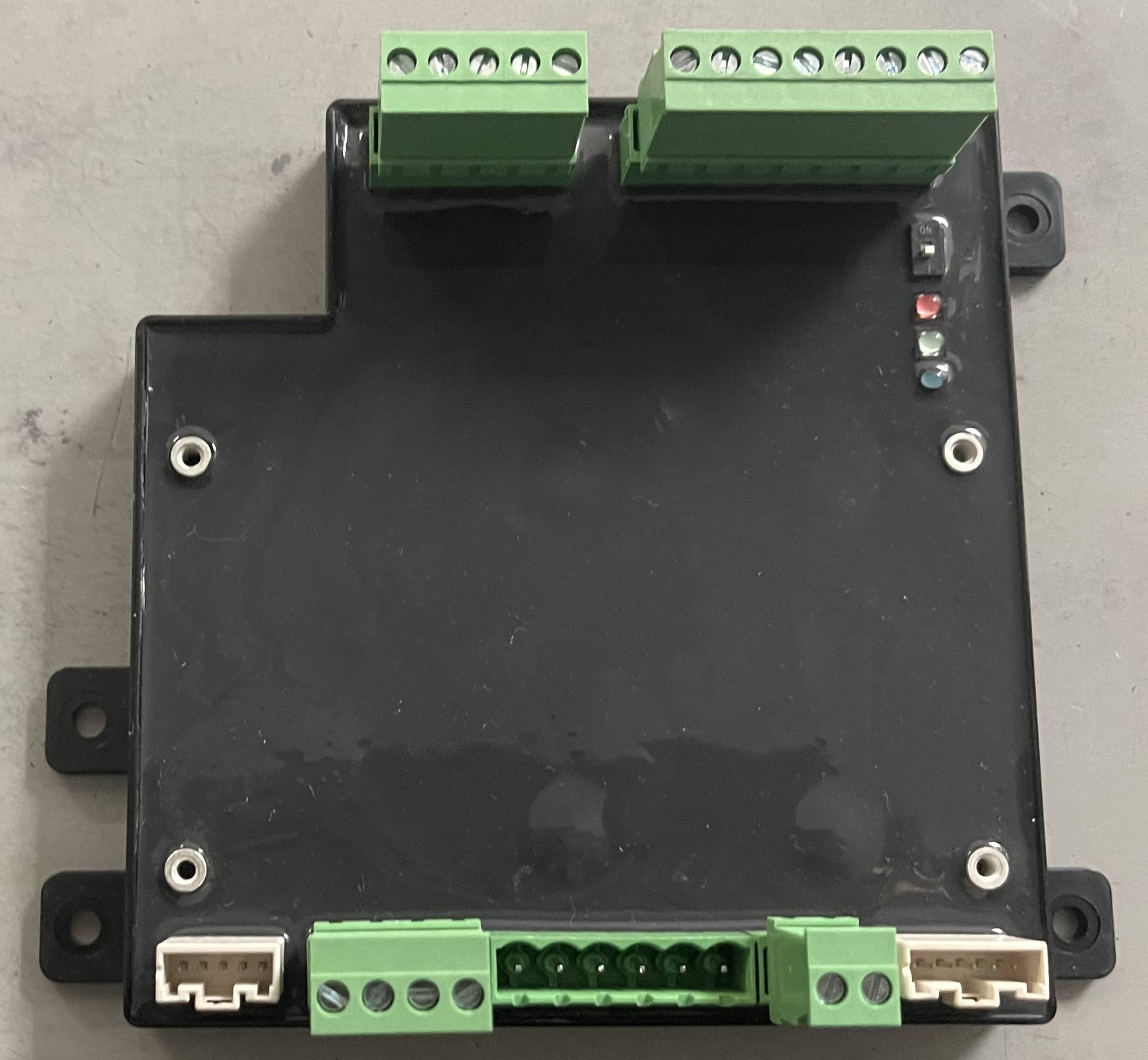

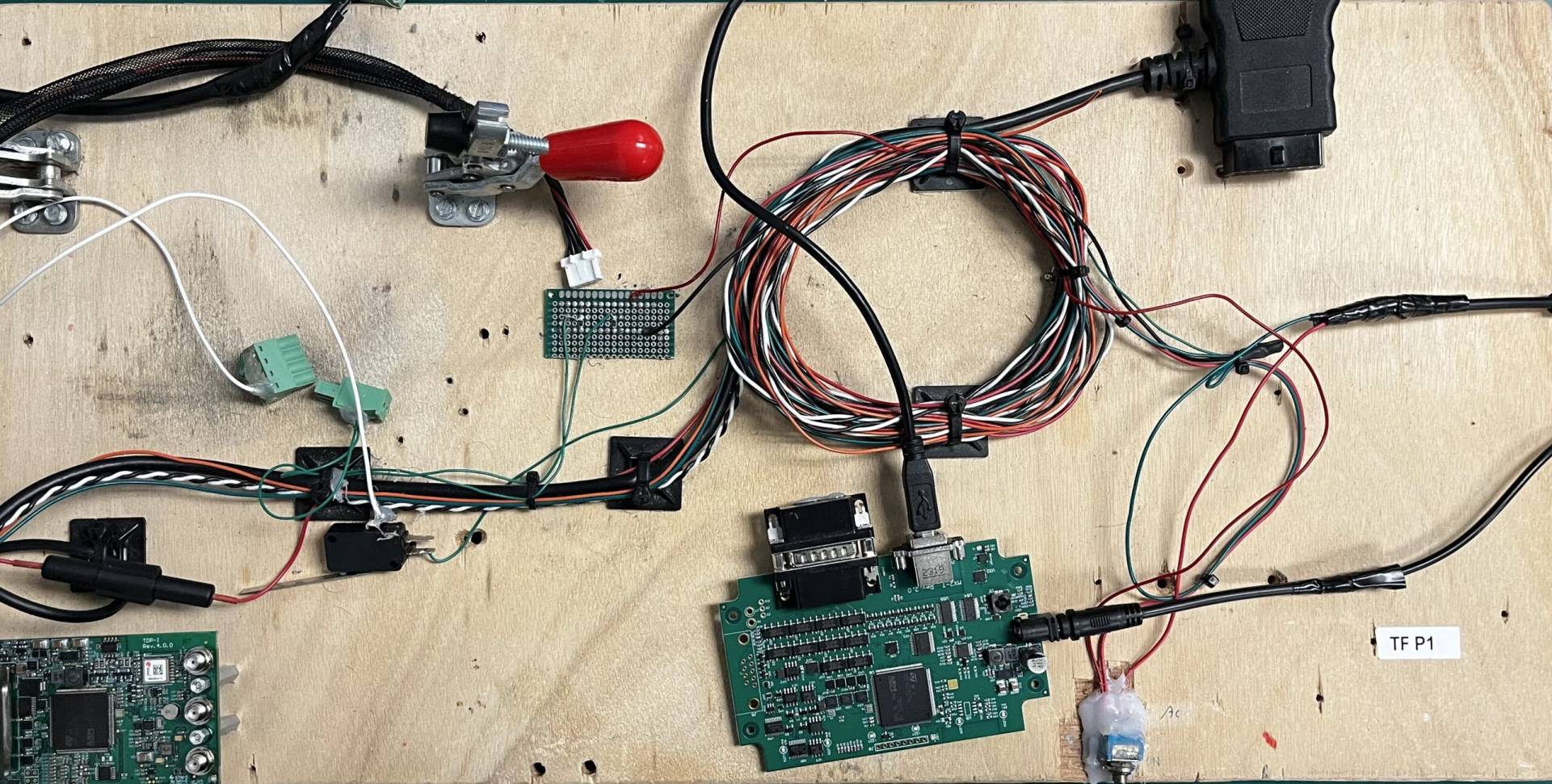

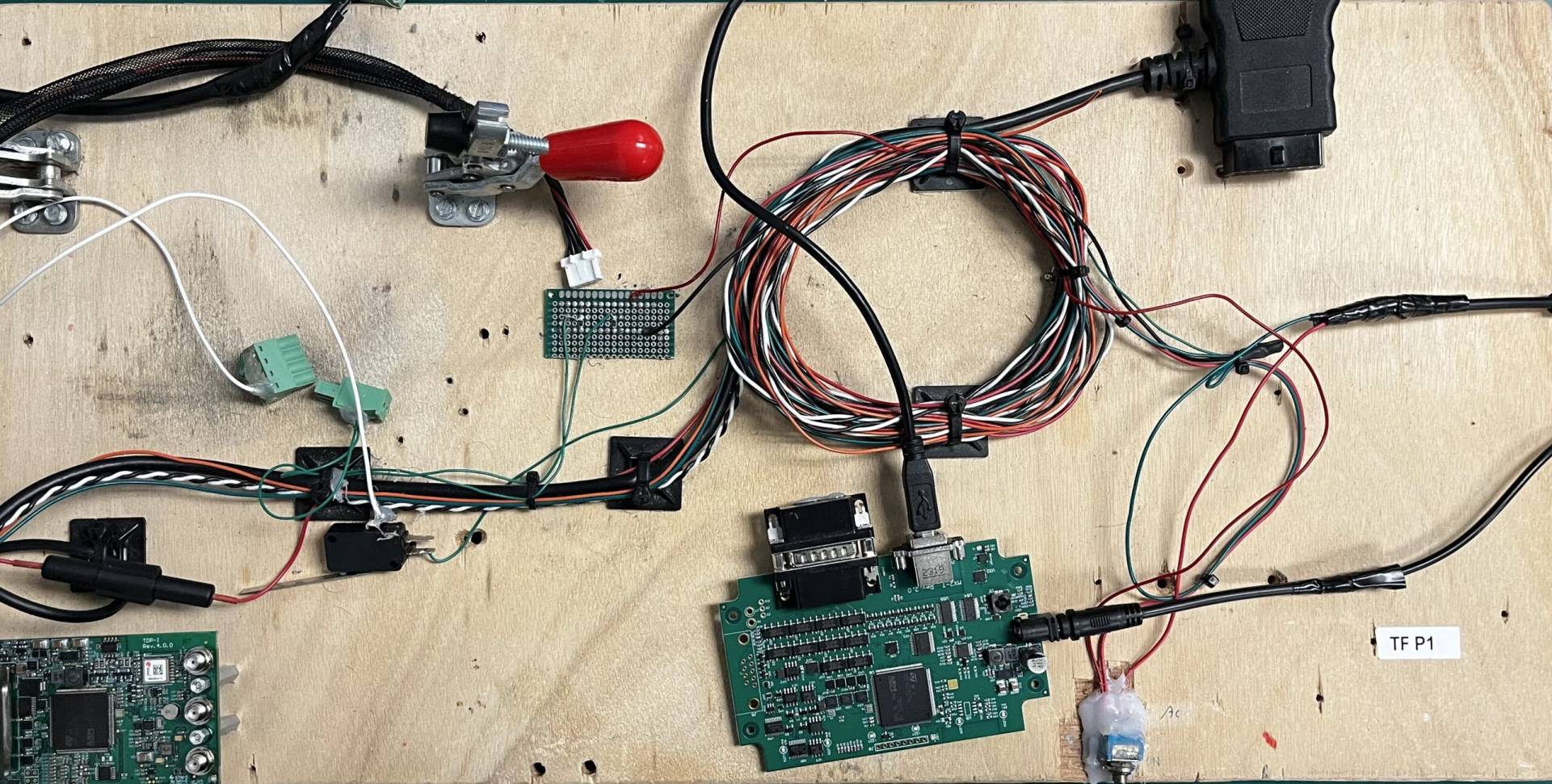

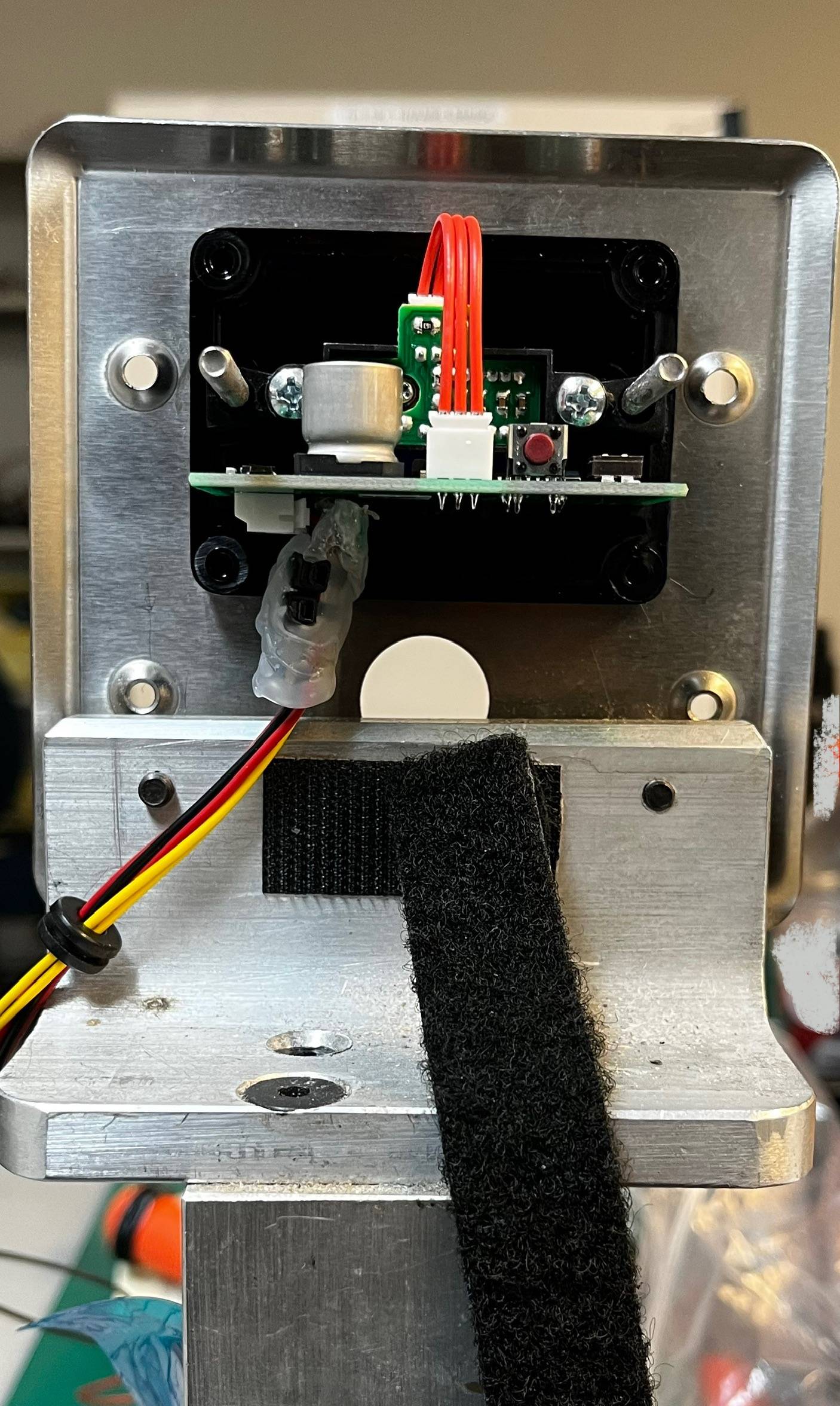

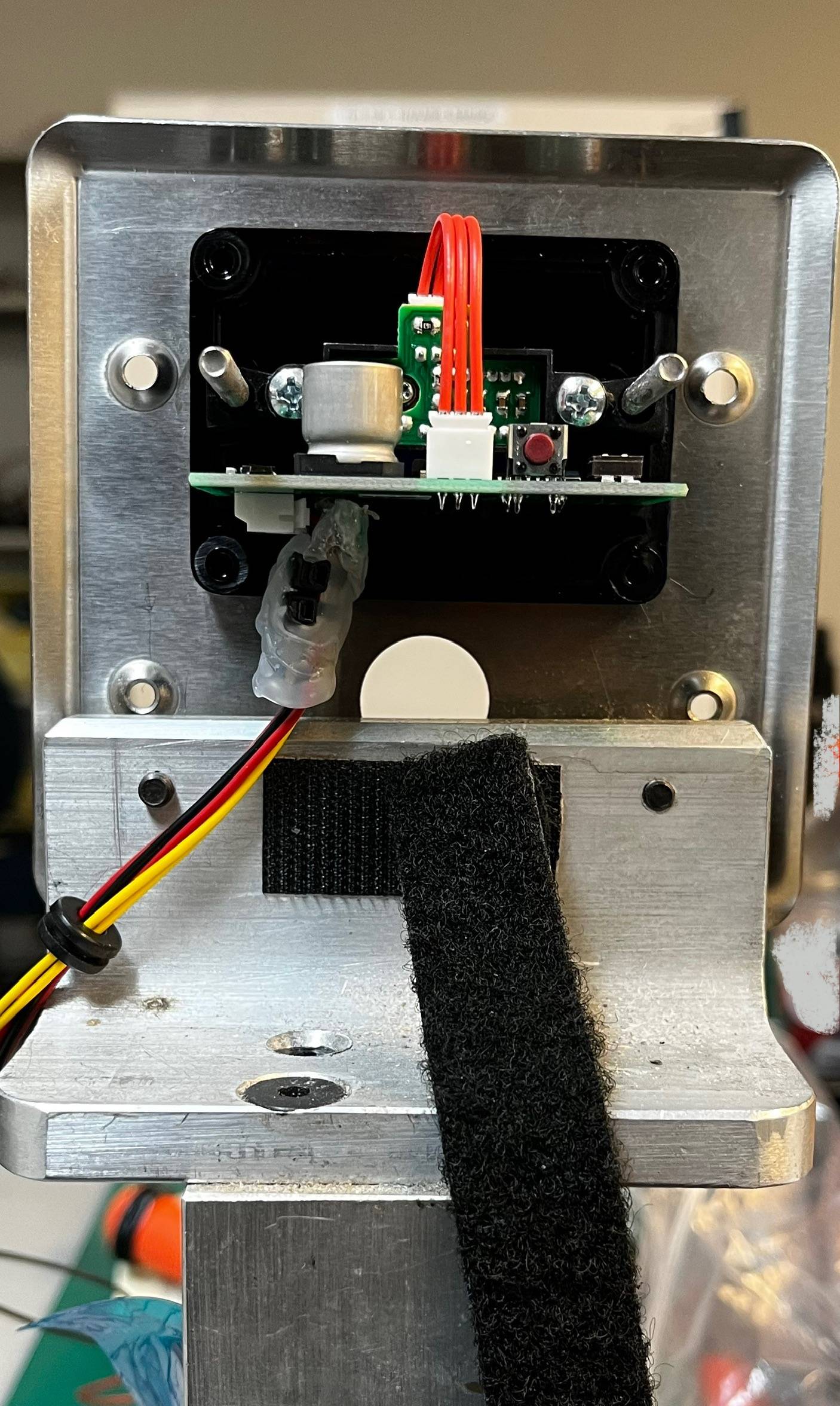

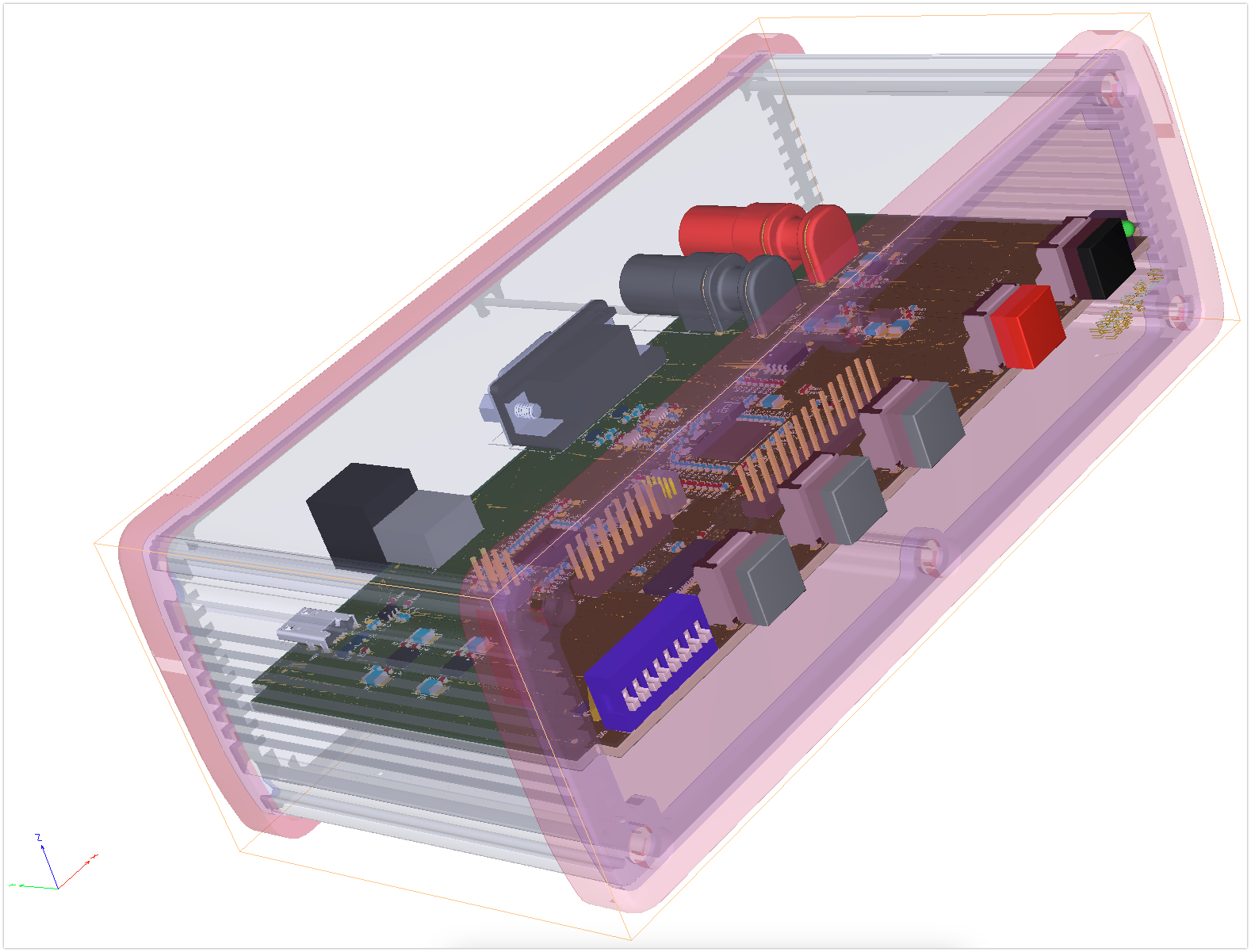

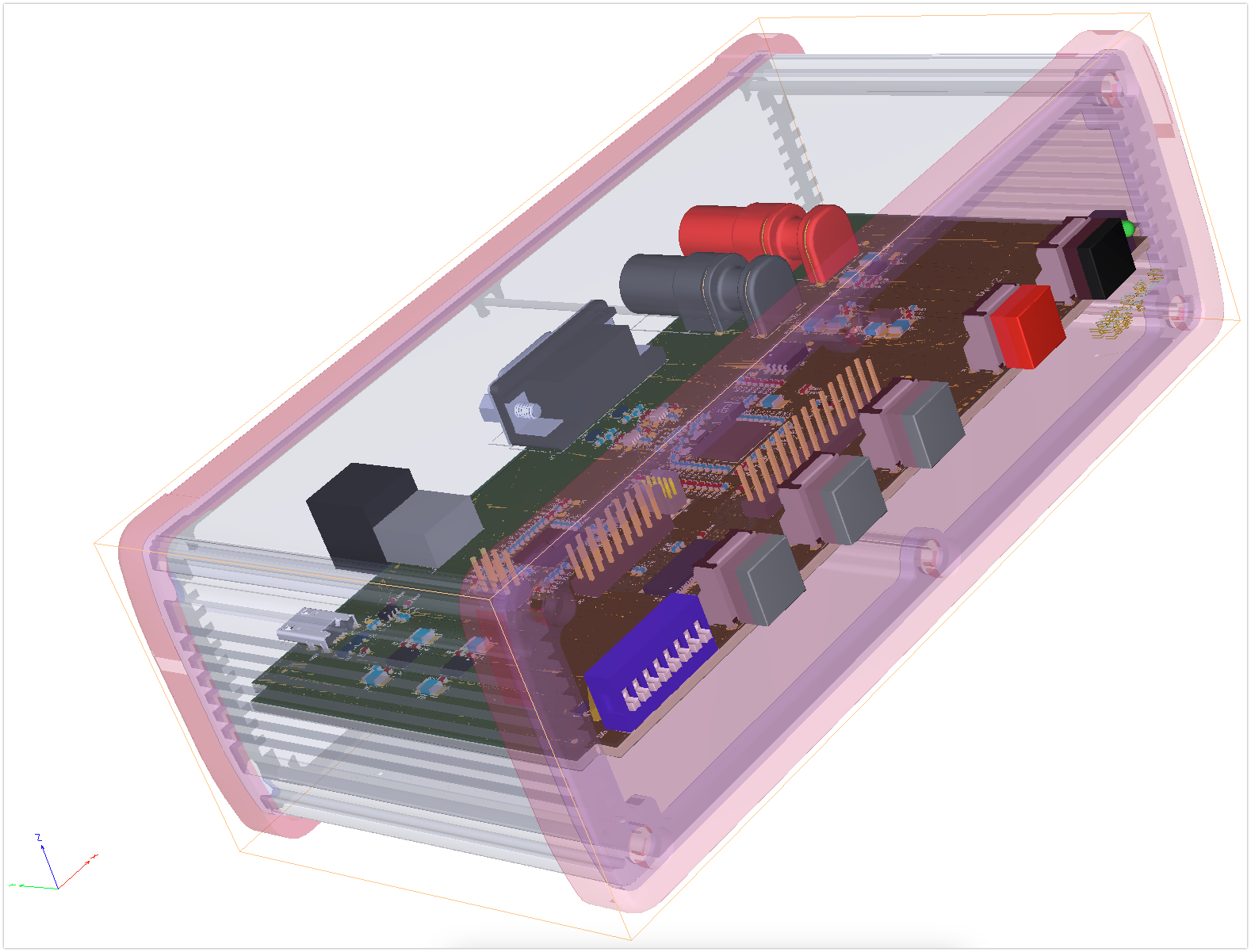

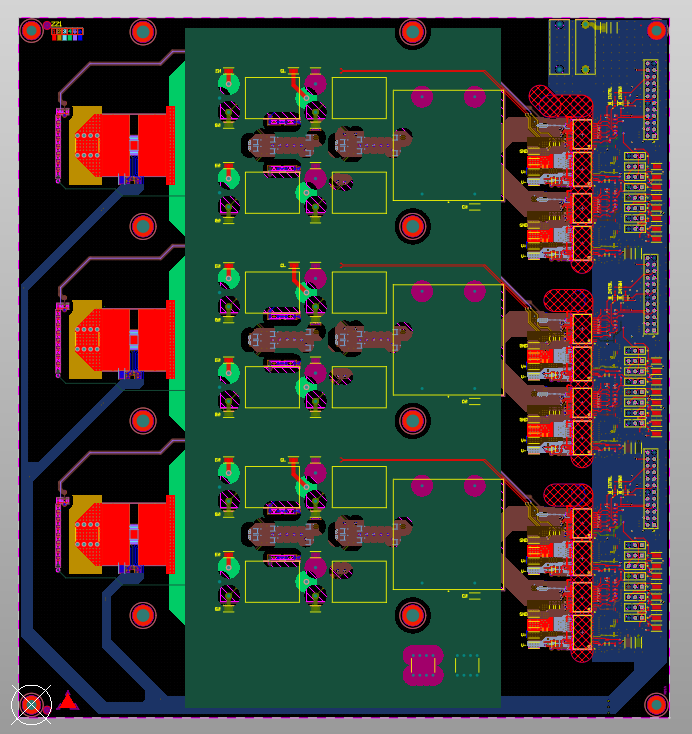

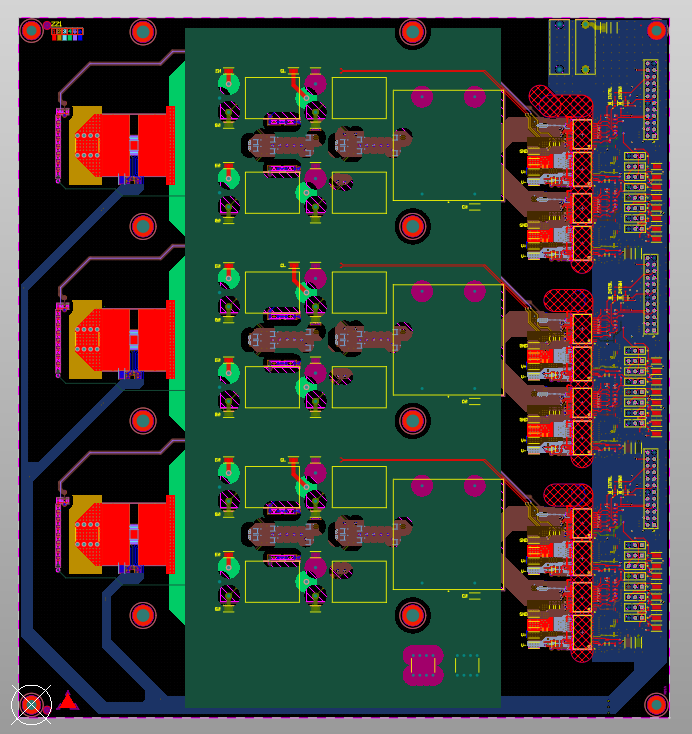

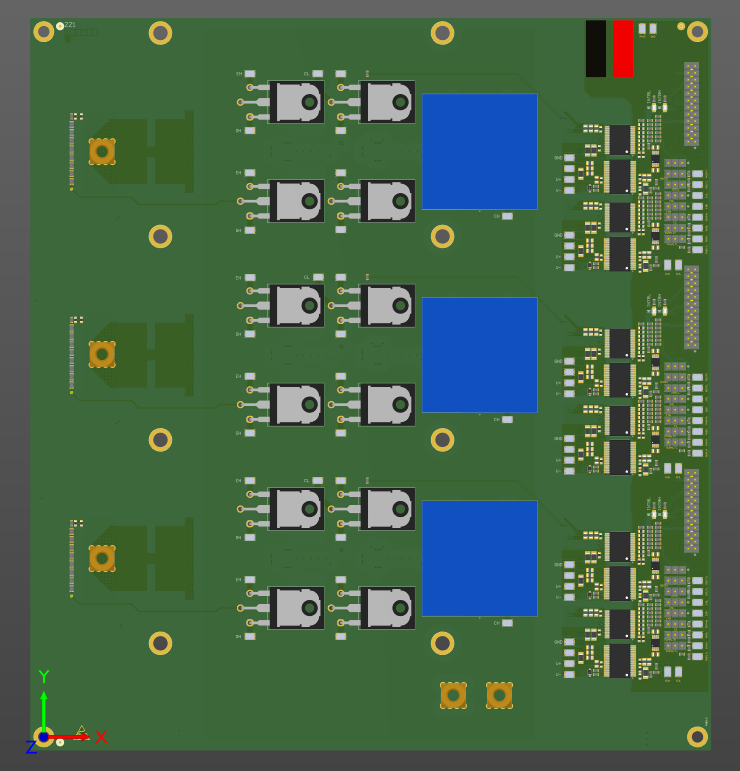

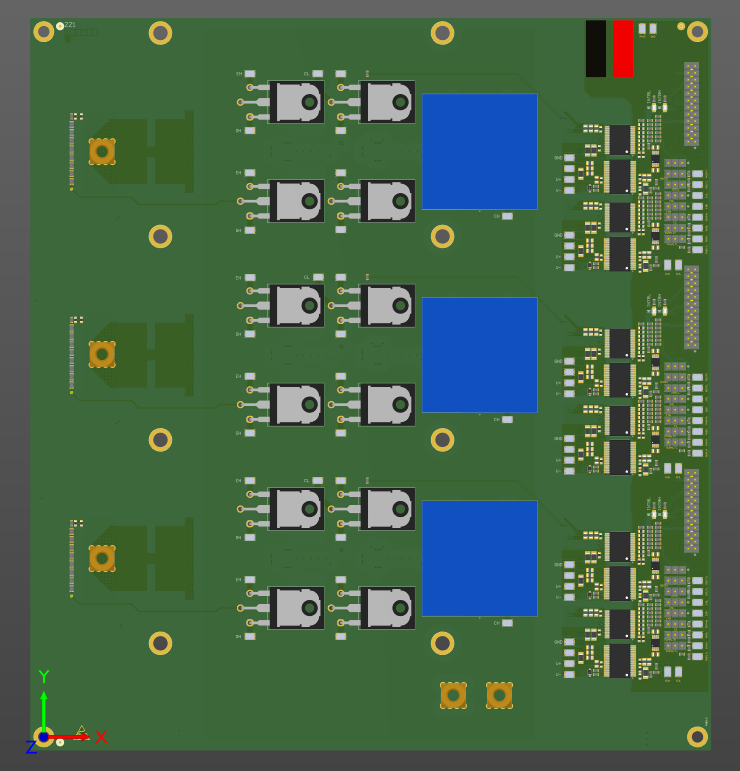

After layout and design, MAKS handles production from A to Z, including printing, assembly, enclosures, 3D integration, traceability, automated and X-ray inspection, functional testing, and shipping, ensuring a seamless and reliable process.

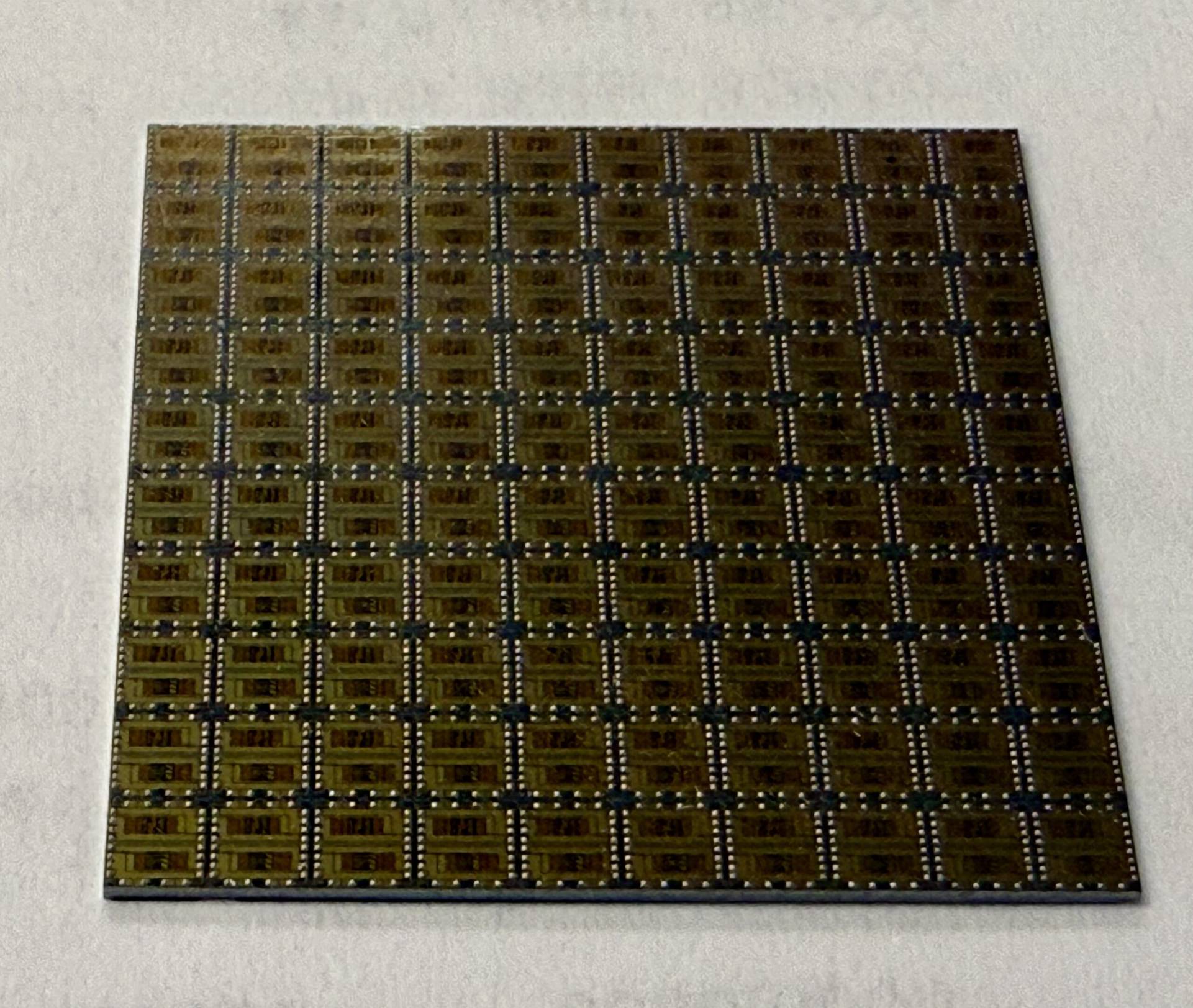

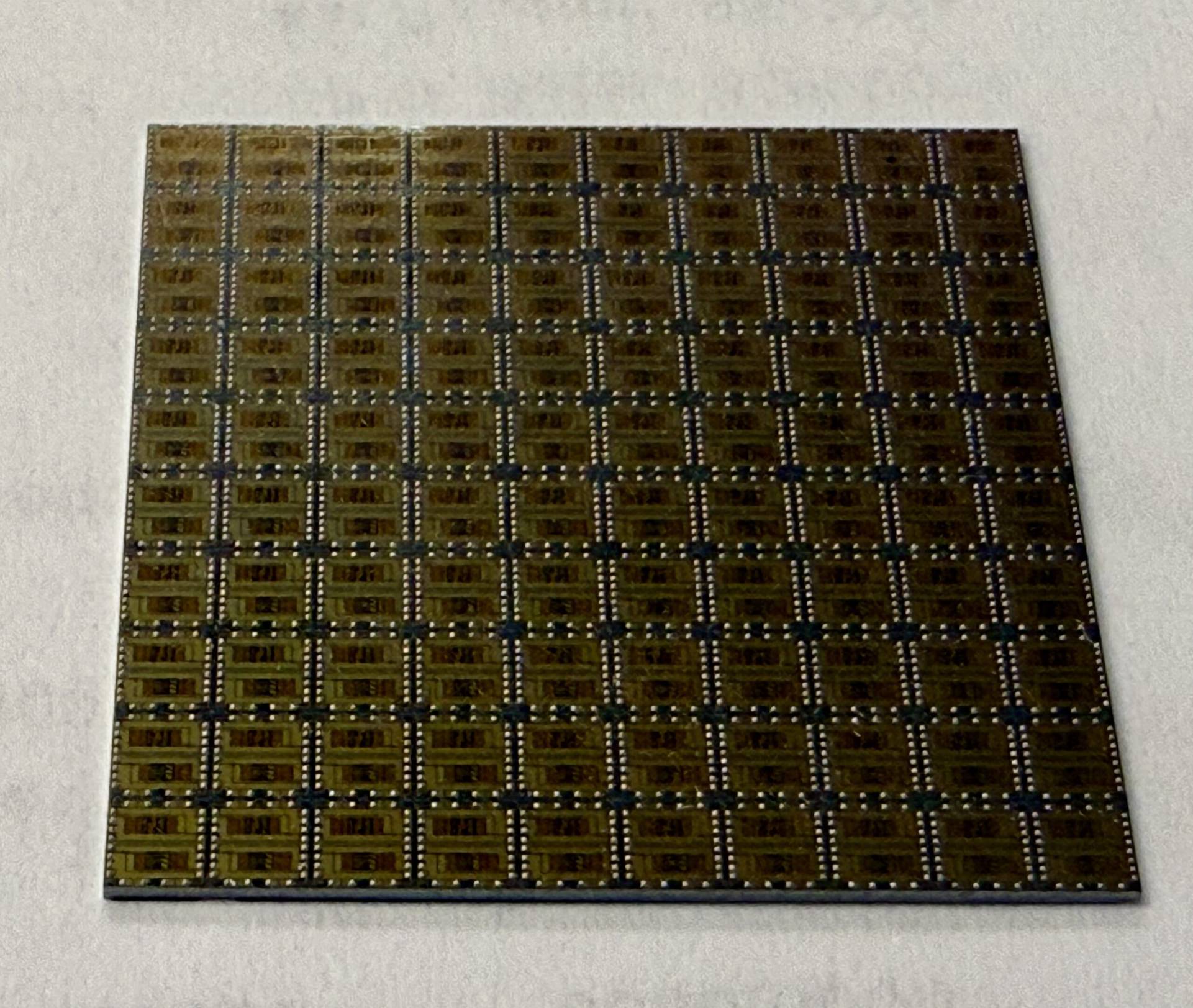

Our team specializes in handling ultra-fine pitch components, including BGAs with up to 2400 balls, a 0.167mm ball diameter, and a 0.4mm pitch. We excel in assembling intricate designs with unmatched precision.

For traditional and fine-pitch solder paste application, our stencil and screen printers provide consistent and high-quality results across all PCB layouts.

We employ precision jet printing technology for solder paste application, ideal for intricate designs and components where traditional methods might fall short.

Our state-of-the-art assembly lines are optimized for both prototype runs and high-volume production, offering flexibility and scalability to meet your project needs.

Our Automated Optical Inspection (AOI) systems with 3D functionality can inspect solder paste height and other critical features, ensuring every board meets stringent quality standards.

We offer X-ray inspection with 3D imaging capabilities, perfect for detecting hidden defects in complex assemblies like BGAs and other densely packed components.

MAKS now offers additional services, including cable harness assembly, potting and molding, custom box building, and more, delivering comprehensive solutions for your electronic manufacturing needs.